Features

Aggregates

Crushing Week

Education

Event Reports

Heavy Equipment

Plenty to see and do at 2024’s World of Asphalt/AGG1

Popular industry trade show runs March 25 to 27 in Nashville.

March 7, 2024 By Mike Lacey

The BKT-EARTHMAX SR 53 is an all steel radial tire specially designed for loaders, dozers and low profile dump trucks (LPDT) operating in severe rocky conditions.

The BKT-EARTHMAX SR 53 is an all steel radial tire specially designed for loaders, dozers and low profile dump trucks (LPDT) operating in severe rocky conditions. World of Asphalt and AGG1 Aggregates Academy & Expo returns to Nashville, Tenn. from March 25 to 27.

More than 400 exhibitors will be on display at the popular show, which features a lineup of the top manufacturers and service providers of the asphalt industry.

Below is a small sampling of what visitors will see.

BKT USA Inc.

Booth: 353

BKT, one of the world’s leading manufacturers of off-highway tires, will have various promotional giveaways at its booth, including baseball caps, Bik & Tik coloring supplies, EARTHMAX keychains and soccer balls.

The following products will be featured:

EARTHMAX SR 41: An all steel radial tire for articulated dump trucks, loaders and dozers. Thanks to its all-steel structure and special block pattern, EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tire ensures extraordinary comfort.

EARTHMAX SR 45: An all steel radial tire specially designed for rigid haul trucks. EARTHMAX SR 45 is the ideal tire for all operations requiring high traction.

EARTHMAX SR 53: An all steel radial tire specially designed for loaders, dozers and low profile dump trucks (LPDT) operating in severe rocky conditions, including underground operations and scrap yards. The deep L-5 tread and the cut-resistant compound provide an extended wear life in addition to excellent traction and stability.

Haver & Boecker Niagara

Booth: 923

Haver & Boecker Niagara’s Niagara F-Class vibrating screen.

Haver & Boecker Niagara’s Niagara F-Class vibrating screen features new technology for simplified maintenance combined with maximum performance and longevity. The updated design retains the technical benefits the original F-Class is known for, such as improving performance in material stratification and reducing blinding and pegging.

The vibrating screen is primarily manufactured with vibration-resistant lockbolts instead of the traditional welding. Lockbolts are more effective at maintaining structural integrity during operation while making vibrating screen maintenance more convenient, safer and cost-effective. Additionally, the company redesigned the flat deck models to create the largest amount of open area possible.

Haver & Boecker Niagara have also redesigned the flat deck models of the new F-Class to create the largest amount of open area possible for modular screen media. Featuring replaceable polyurethane anchors, the new high open area modular deck is suitable for virtually any pin and sleeve modular screen media.

The F-Class is available with a variety of configurations and upgrades, and can be used in both stationary and portable applications.

Major

Booth: 923

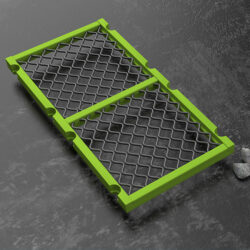

MAJOR’S FLEX-MAT Modular PLUS.

MAJOR offers FLEX-MAT Modular PLUS, which is specially designed to withstand harsh screening conditions with the most abrasive materials, such as granite and basalt. The advanced screen media offers all the benefits of FLEX-MAT — high open area, efficient stratification, no blinding or pegging — combined with a new and improved wear life comparable to polyurethane screen media. Additionally, the media offers up to five times longer wear life than traditional woven wire and produces a cleaner retained product.

The efficiency-enhancing design of all FLEX-MAT screen media, including the modular PLUS series, allows the wires to vibrate independently from end to end under material contact. The high frequency of the wires — 8,000 to 10,000 cycles per minute — adds to the vibration of the screen box — 800 to 900 cycles per minute — to speed up material separation and passing.

The new PLUS series is available in the D, S and T series. FLEX-MAT Modular PLUS screen media panels are available in either the patented OPTIMUMWIRE or 304 stainless steel wire.

Martin Engineering

Booth: 305

Martin Engineering delivers tough, tested and innovative material handling solutions, backed by ndustry experience. Specializing in belt cleaning, belt support, belt alignment, belt sealing, dust management, flow aid solutions and more, Martin offers products specifically suited for the aggregate industry.

Products on display include:

Martin Engineering N2 Position Indicator: Martin Engineering’s intuitive N2 Position Indicator allows for remote monitoring of the belt cleaner blade via Martin’s proprietary mobile app, indicating remaining blade life, notifying when re-tensioning or replacement is required and warning in the event the blade is no longer in contact with the belt. The N2 Position Indicator will collect data and provide information on any belt cleaner utilizing a Martin blade.

Canoe Liner: Installed inside conveyor transfer point skirtboards, Martin Manufactured Canoe Liners absorb impact and abrasion and creates a dam to shield the sealing system from the weight of the material load, prolonging the life of the seal. Martin manufactured Canoe Liners feature a steel plate molded inside the urethane to prevent bond issues. Liners are also stackable to line higher drop chutes.

Martin Air Cannons: When material is hung up in a hopper or head chute of a conveyor transfer point, it can force a shut down during shifts to get the process back online. Instead of using hammers or lances to clear material, Martin Air Cannons offer another approach. Air cannons provide a controlled blast of air to clear material blockages and maintain proper material flow.

McCloskey International Ltd.

Booth: 901

McCloskey’s mobile C3 Cone Crusher.

McCloskey International leads the mobile aggregate screening and crushing industry with a complete line of equipment including crushers and screeners.

J6 Jaw Crusher: Designed to thrive in the most challenging environments, McCloskey International states the J6 jaw crusher is not only resilient, but powerful and reliable. The company boasts the J6 has unmatched performance with its jaw chamber configuration and optimized material circulation, and the design not only ensures superior durability but also that the machine achieves high throughputs. The large chamber tackles some of the toughest materials and the J6 also features an optional factory fit rock hammer for added versatility.

C3 Cone Crusher: The mobile C3 Cone Crusher has been designed to deliver superior performance while also achieving higher capacity, better product quality, optimum versatility and improved fuel efficiency. The C3 cone crusher is equipped with a powerful and efficient cone with a hydraulic closed side setting (CSS) adjustment allowing for consistent and precise product sizing. The C3’s large feed opening allows the crusher to accept larger feed sizes, increasing throughput and reducing the risk of bridging, where material gets stuck in the crusher. This crusher can handle a wide range of materials and applications, including secondary and tertiary crushing. The C3 optimizes power utilization while maintaining high crushing efficiency. Its direct drive and variable speed reduce energy consumption and operational costs. The C3 also comes with features like a large high-resolution control panel display with full machine monitoring and remote monitoring with 365Connex Telematics, optimizing the crusher’s performance and ensuring efficient operation even in varying conditions.

Polydeck

Booth: 723

Polydeck has distinguished itself as the leading provider of modular synthetic screening media and comprehensive screening solutions.

Visit the Polydeck booth to learn how the company will provide a free plant survey to anyone located in North America. The company’s screening experts will review your screen media along with wear and static parts. Their comprehensive analysis will equip you with the insights needed to enhance your screens for optimal performance, achieving higher throughput at lower costs.

Feature products on display include:

RUBBERDEX ULTRAMAX: Ultra-high open area modular rubber screen media.

METALDEX ULTRACLEAN: Ultra-high open area modular wire screen media with integrated secondary movement to eliminate plugging and blinding.

PROTEX UC: Urethane coating that fully seals steel to extend life of equipment, provide abrasion and tear protection, and reduce noise pollution.

Superior Industries

Booth: 517

The Cemco T80 Single Drive will be on display at Superior Industries’ booth.

After acquiring CEMCO last year, Superior Industries rebranded the company name, but maintains the name and design of the 60-year-old CEMCO Vertical Shaft Impact Crusher.

A T80 single drive model of the pioneering VSI will be on display in Superior’s booth at AGG1. Notable features include an interchangeable crushing chamber that accommodates multiple rotor and anvil configurations, a hydraulic lid lifter, and an adjustable feed tube. Superior’s CEMCO VSI is available in seven models with production rates up to 450 tons per hour.

Tecweigh-Tecnetics Industries

Booth: 1101

For 50 years, Techweigh has provided durable, accurate and reliable in-motion feeding, weighing and metering equipment for dry material handling needs. The following items will be featured at the company’s booth:

WY10 Belt Scale: The Tecweigh WY10 Single Idler Conveyor Scale is the most dependable and rugged belt scale on the market. Weather-tight one-piece construction keeps your line rolling, even in the most extreme conditions: dust, dirt and harsh weather. The WY10 utilizes LVDT load sensor technology. LVDT load sensors simply can’t be overloaded and are far less susceptible to damage from lightning strikes, reducing changes of blown load cells.

HY15 Belt Scale: The HY15 Hybrid Belt Scale was designed to incorporate the Tecweigh electronics package with the less costly modular scale frame design. The compact, low-profile design is suitable for many conveyor applications, including mobile units. Made with heavy-duty cold rolled steel, the HY15 will withstand the harshest environments. Featuring two NTEP approved strain-gauge load cells, the HY15 offers a single-idler accuracy of one-half to 1 per cent. The dual-idler HY25 model provides an accuracy of one-quarter to one-half per cent. These scales come with a complete installation kit, mechanical overload protection, signal conditioning enclosure, calibration weight brackets, speed sensor, and Tecweigh’s standard five-year warranty. Tecweigh’s Hybrid Belt Scales can also be provided with optional features including wireless communication, multi-scale processor, printer, remote displays and more.

WY15 Belt Scale: Keeping with Tecweigh’s tradition of unbeatable accuracy, dependability and ease of use leads the company to combine its unique time and labour-saving belt scale features with strain gauge load cell technology in its WY15 Conveyor Scale. The Tecweigh WY15 Single Idler Conveyor Scale utilizes two NTEP approved bending-beam load cells, features rigid all-welded construction. It is backed with a five-year warranty.

Terex MPS (Minerals Processing Systems)

Booth: 357

Terex MPS is a leading provider in the crushing and screening industry. Comprising three legacy brands – Canica, Cedarapids and Simplicity – Terex MPS supplies a range of crushing and screening equipment across key industries, including mining, aggregates, demolition and recycling, and industrial minerals.

Terex MPS offers a diverse product line, including modular, portable and static equipment designed to produce the highest quality end products. The equipment caters to the processing needs of hard and soft rock, sand and gravel, ore, and industrial minerals.

The company’s team of product specialists will be on hand at AGG1. The event supplies a platform to share insights, contribute to conversations and highlight the latest advancements shaping the future of crushing and screening. AGG1 presents an opportunity to collaborate directly with Terex MPS’ distribution network to discuss and address the evolving needs of customers.

Weir ESCO

Booth: 431

Weir ESCO is a developer, manufacturer and provider of components for mining, construction and industrial applications. The company’s booth will feature its latest products, including:

- Crusher wear parts

- Bucket GET, teeth and lip systems

- Construction excavator and wheel loader buckets and attachments

- Blades, end bits and cutting edges

Motion Metrics has recently joined Weir ESCO. Stop by the booth and learn how these smart products can provide data solutions that improve quarry safety and energy efficiency.

LoaderMetrics cameras will mitigate the risk of crusher obstructions caused by missing teeth. Motion Metrics LoaderMetrics cameras use artificial intelligence and thermal imaging to provide accurate missing tooth detection for all loader types. This alerts operators to missing teeth before the teeth travel downstream and obstruct crushers.

Motion Metrics’ proprietary lens-cleaning system ensures accurate performance under the harshest environmental conditions. The hardware is built to meet or exceed military standards for temperature, shock, vibration and dust.

Weiler

Booth: 2349

Weiler MTVs are designed with innovative features to increase productivity while reducing operating costs, and are available with front- and rear- mounted operating platforms.

Weiler commercial pavers bring reliable, heavy-duty design and components to the commercial paving market.

Weiler road wideners feature durable designs in the right size machine for the job. The S200 soil stabilizer provides high production in a variety of applications with both a soil and combination rotor option.

The D560 and D460 rock drills rely on a proven hammer design and are the only drill built in North America.

Print this page