Features

Aggregates

Roads & Paving

Column: A lifetime of service

Part 1: A conversation with Ken Monlux

September 21, 2020 By Rock to Road staff

Photo credit: © Pavlo / Adobe Stock

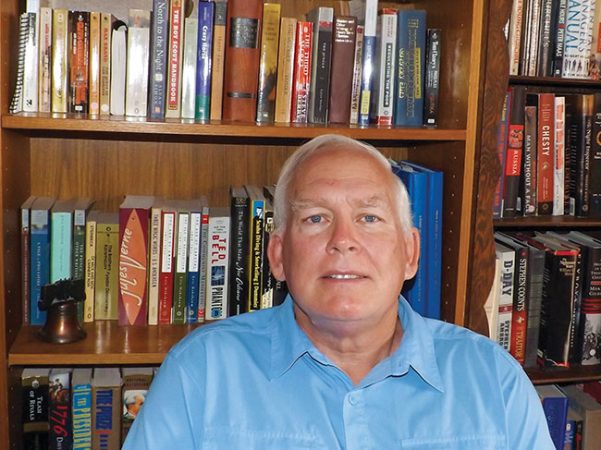

Photo credit: © Pavlo / Adobe Stock Rock to Road prides itself on showcasing interesting operations and projects and the up and comers in the industry. Now we’re excited to bring you, the readers, another regular section in the magazine. We will be regularly featuring industry members who have dedicated their lives to careers in the roadbuilding and/or aggregates industry. The first interview subject is Ken Monlux, a consultant, who specialized in operational management issues. Monlux has over 30 years of experience in hot mix plant operations, ready mix concrete operations and environmental clean-up and permitting.

1. Can you provide a thumbnail

description of your early experiences in the material side of the Heavy Construction industry?

My career started at the age of 15. I worked summers, first as a labourer, then moving to the scale house and finally to the lab. I started in a small locally owned sand and gravel site, then in my college years moved to a small regional company. After college, I accepted a full-time position with the regional company that I was working for. My job was twofold:

a. Operate the soils lab for three quarry sites, two CTB plants and two hot mix plants. Performing Q.C. inspections for:

- Airports;

- State, county, and local projects; and;

- Interface with customers.

b. Safety officer for the entire company (MSHA, OSHA, and employee training).

2. What was your first managerial position?

At some point, I felt I had learned what I could and was looking for a managerial position. I accepted a position with a large regional company as a hot mix plant manager. The position had responsibility for two 8,000 lb. batch plants and an emulsion plant, tank farm with trucking. The interesting point of this position was that we operated at high demand and production rates. Without an in-house paving crew, we serviced only outside customers. These sites were under a union(s) agreement. In addition, the plants were located in an urban setting. In fact, our market area evolved into the San Francisco Silicon Valley.

3.The late 70’s and early 80’s were a transition time for the hot mix industry, can you comment on the changes?

- a. From wet scrubber to bag house to control dust;

- b. The use of surge storage of finished material;

- c. The advancement in controls and proportioning equipment;

- d. The growth of the drum plant from use as a portable to a fixed location plant; and

- e. The added layers of agencies oversite and permitting.

Of all the changes we worked through in this time period, I would say the added layers of agencies’ oversite and permitting provided the biggest challenges to our operations. Not only were we facing a steep learning curve, we were working with various agencies with ever changing goals. I started to understand the time demand, testing, and cost that this new aspect to our business would entail.

Operational use permits have become one of the largest assets attached to the plant site. Going forward, permits will become more costly and difficult to acquire and maintain.

4. When was your first exposure to recycling?

Although recycling material for road base began earlier, I started experimenting with hot mix in the early 80’s. At first, we were adding 10 per cent in the boot of the hot bucket elevator. Over the years, I worked with various materials recycled into the mix with good and sometimes not so good results:

- A. Asphalt: up to 30 per cent;

- B. Crushed waste concrete;

- C. Asphalt roofing tiles;

- D. Glass: replacement for sand (very dry);

- E. Rubber tires: both liquid and chips;

- F. Refinery waste: filler between one and three per cent;

- G. Spent sandblasting grit: up to 10 per cent replacement for sand;

- H. Off spec jet fuel: as a fuel for the main burner and heating tanks; and

- I. Shredded old dollars from the U.S. Mint (at the request of the Mint we made test runs by injecting shredded dollars directly into the drum).

5. In 1989, along with your duties at the hot mix plants, you headed an environmental service division. Can you give an overview?

Based on the success we were having in recycling and the changing environmental laws in California, we found the company evolving into the emerging environmental cleanup industry. I headed up a new division that used the material handling expertise in a new and exciting way. Our business model focuses on two types of cleanup projects:

- Cleaning of soil from underground fuel tanks (mostly gas stations) This was a hot process performed at the plant site. This process was limited to about a 50-mile radius of the plant.

- The recycling of metal contaminated soil into an emulsified treated base (ETB) This was an on-site cold process producing a road-base material. We worked this on-site process throughout the western United States (If anyone would like more information about the processes, please contact me).

Ken Monlux

6. What are the lessons learned from the environmental cleanup industry that you brought back to the construction materials industry?

The time I spent in the environmental industry taught me the discipline of documentation of my actions. Every step of every project needed to be planned, approved and documented. Every project was unique. We worked with a wide variety of agencies to get needed approvals. Every project had a plan including safety, and chain of custody that needed to be adhered to. It taught me the need to study the logistic demands every step of the way. Every project, both on-site or the plant process had a follow up report of all actions including an accounting of all materials used. Overall, this experience made me a better manager. It improved my communication skills and taught me how to work with outside agencies.

7. How is it you went from environmental clean-up, and hot mix to ready-mix concrete?

At a certain point, the environment division was spun off to a major environmental company. I had a time commitment to go with the sale. When my commitment was satisfied, I was approached and accepted an executive operational position with a ready-mix concrete company. I enjoyed ready-mix, but my heart has always been in hot mix.

8. After retirement, why did you decide to re-enter the materials industry and what is it you feel you can offer?

In hindsight, I retired too early. It was not long before I was reading and taking an interest in what was happening in the industry that treated me so well. I had a chance to talk with current executives and lend a hand where I could. I was invited to workshops and in-house training sessions to share some of my understandings. I felt I had insight and experiences that can be of a benefit to today’s companies. I knew that I could provide services on a cost effective and as needed bases.

In order to get some exposure, I started to write operational management articles for various trade magazines and produce a monthly newsletter delivered to industry via email. I have also created and further develop a plant reporting platform to aid in the development of the plant manager and crew.

9. Where do you see the hot mix industry going in the future?

I see automation increasing allowing for mixes to become more complex. Admixtures, fillers, and high percentage of various recycled materials will grow. These mixes will be produced hot, warm, and cold. The use of emulsions will continue to expand. I see the plant’s production rates will increase to a point they will outstrip the ability to allow the quality control department to keep up. Additional pressure will be placed on the crew with regard to operational time, and their ability to maintain a quality product. As stated above, the cost and ability to get and maintain operational permits will be more difficult. In some geographic areas the ability to acquire high quality cold feed aggregates in a cost-effective manner will be a concern. I am also worried about the continuing consolidation of companies leading to a few corporations controlling the industry.

When you get down to it, hot mix asphalt will always be a regional industry with local markets and a defined product shelf life.

10. What are some of the challenges you see today facing an owner, or executive team?

The ability to recruit, train, motivate, and retain crews and managers. We compete with other industries for talented employees, and we need to keep evolving to attract the best and brightest. We have to understand that our industry demands a lot from our employees.

We work in a demanding industry, from the president to the labourer we have to by actions demonstrate a work ethic that reflect those demands. Owners need to invest in training and continuing education to retain the managers of the future.

We have to do all in our power to provide a clean, safe, and motivating environment in which to work. Finally, we need to allow our manager to manage. What do I mean by this? We need to succeed and sometimes fail in order to grow. We need our managers to have the ability to work their way out of a jam with our support, not always at our direction.

Equipment manufactures will continue to improve the plant and equipment that are design to improve our product. We need to understand that automation is a double edge sword, allowing for improve production but at a cost of a human disconnect.

I believe it is up to us, to work with crews, plant and regional managers to ensure an improved cost-effective product, market, with customer satisfaction.

If you have any questions or comments, Ken Monlux can be reached at kenmonlux@yahoo.com.

Know someone you would like to see featured for their lifetime of service in the industry? Contact editor Andrew Snook at

asnook@annexbusinessmedia.com.

Print this page