Features

Products & Equipment

Aggregates

Heavy Equipment

Pits & Quarries

Equipment Spotlight: Screen time

April 1, 2021 By Rock to Road staff report

A look at the latest screening technologies:

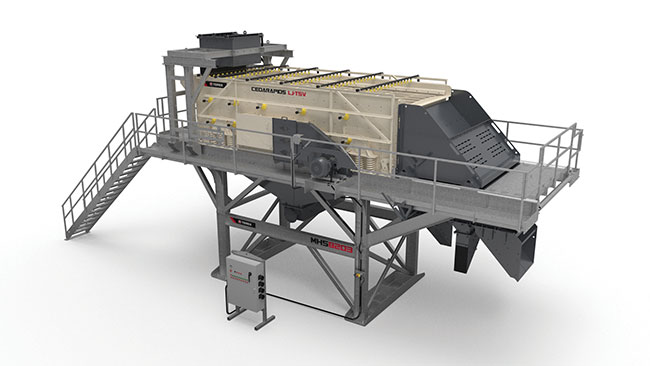

CEDARAPIDS

Cedarapids is proud to introduce new options for the popular MHS8203 and MHS6203 screen modules including a wash plant option and a feed box and support structure for dry screening. The screen modules feature the proven TSV Series horizontal screens, combining the efficient, high g-force El-Jay oval stroke action and a large blending chute for a range of discharge options. The new wash plant option includes a feed box with two spray bars and support structure, screen spray system with manifold and under screen flume. The new Rock Box Style material feed box allows for the conveyor to feed from either side or over the back of the screen.

terex.com

CDE

CDE Infinity Screens patented screening technology features a unique range of circular and linear motion screens for optimal performance; and offer superior screening and classification for your materials. The patented Trilogy side wall construction offers increased strength, while eliminating unnecessary weight. The unique VibroCentric and VibroSync drive mechanisms enable advanced screening and dewatering performance. The units feature a weld-free construction and a galvanized screen structure for enhanced protection, longevity and durability. The Infinity Screens are designed to handle a wide variety of applications.

CDE Infinity Screens patented screening technology features a unique range of circular and linear motion screens for optimal performance; and offer superior screening and classification for your materials. The patented Trilogy side wall construction offers increased strength, while eliminating unnecessary weight. The unique VibroCentric and VibroSync drive mechanisms enable advanced screening and dewatering performance. The units feature a weld-free construction and a galvanized screen structure for enhanced protection, longevity and durability. The Infinity Screens are designed to handle a wide variety of applications.

cdeusa.com

KEESTRACK

For some of the highest performance in mobile screening, the Keestrack K7’s massive feed hopper and screening surface can handle the toughest material in mining or quarrying applications. Offering a high production and throughput up to 1,000 tph, the Keestrack K7’s offers a 2- or 3-way split designed for heavy-duty scalping. Additional highlights include a hydraulically lifting screenbox for ease of maintenance and screening media changes, load sensing technologies for reduced fuel consumption, hydraulic controls for fine-tuning of production, and superior surface protection for long-term durability.

For some of the highest performance in mobile screening, the Keestrack K7’s massive feed hopper and screening surface can handle the toughest material in mining or quarrying applications. Offering a high production and throughput up to 1,000 tph, the Keestrack K7’s offers a 2- or 3-way split designed for heavy-duty scalping. Additional highlights include a hydraulically lifting screenbox for ease of maintenance and screening media changes, load sensing technologies for reduced fuel consumption, hydraulic controls for fine-tuning of production, and superior surface protection for long-term durability.

keestrack.com

frontline-machinery.com

KLEEMANN

The Kleemann mobile screening plant MOBISCREEN MS 953i EVO is equipped with a 102.8-sq.ft. screen casing. The triple-deck screening plant impresses with a feed capacity of up to 500 t/h. and is controlled using an intuitive touchscreen control system, SPECTIVE. As a result, all functions are easy to control and operating statuses and machine functions can be viewed at any time. With a variety of screening material available, it is perfect for natural and recycled material.

The Kleemann mobile screening plant MOBISCREEN MS 953i EVO is equipped with a 102.8-sq.ft. screen casing. The triple-deck screening plant impresses with a feed capacity of up to 500 t/h. and is controlled using an intuitive touchscreen control system, SPECTIVE. As a result, all functions are easy to control and operating statuses and machine functions can be viewed at any time. With a variety of screening material available, it is perfect for natural and recycled material.

wirtgen-group.com

POLYDECK

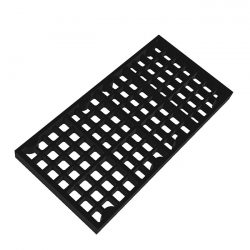

DMax, Polydeck’s latest evolution in modular synthetic screen media, provides so much throughput advantage, its open area rivals that of wire cloth while providing the durability and benefits often associated with modular synthetic screen media panels. DMax offers a significant weight reduction benefit over other synthetic screen media options, which reduces component wear on the screen and increases the effect of the vibrating mechanism’s stroke on particle separation.

DMax, Polydeck’s latest evolution in modular synthetic screen media, provides so much throughput advantage, its open area rivals that of wire cloth while providing the durability and benefits often associated with modular synthetic screen media panels. DMax offers a significant weight reduction benefit over other synthetic screen media options, which reduces component wear on the screen and increases the effect of the vibrating mechanism’s stroke on particle separation.

polydeck.com

SUPERIOR INDUSTRIES

Superior’s Fusion Modular Platform systems offer bulk producers a faster, more economical solution to developing and commissioning a new processing plant. The scalable, pre-engineered systems can also be applied as additions to existing plants. Modular platforms are compact for smaller footprints, offer convenient maintenance features and integrate seamlessly with Superior’s crushing, screening, washing and conveying products. Modularity of design means owners and operators can easily expand the capabilities of their Fusion Platform System as finances allow, application needs change and alongside growing market conditions. Additionally, choosing a pre-engineered configuration means faster lead times and earlier commissioning. Each system is designed with plug-and-play, pre-wired electrical connections and is optimized for efficient shipping by flatbed or container.

Superior’s Fusion Modular Platform systems offer bulk producers a faster, more economical solution to developing and commissioning a new processing plant. The scalable, pre-engineered systems can also be applied as additions to existing plants. Modular platforms are compact for smaller footprints, offer convenient maintenance features and integrate seamlessly with Superior’s crushing, screening, washing and conveying products. Modularity of design means owners and operators can easily expand the capabilities of their Fusion Platform System as finances allow, application needs change and alongside growing market conditions. Additionally, choosing a pre-engineered configuration means faster lead times and earlier commissioning. Each system is designed with plug-and-play, pre-wired electrical connections and is optimized for efficient shipping by flatbed or container.

superior-ind.com

TEREX SIMPLICITY

Simplicity’s DM Series incline screens are uncompromised workhorses designed for heavy-duty scalping, intermediate sizing or finished screening of virtually any material. The DM Series twin shafted dual mechanism delivers rugged reliability for large, heavy production demands with a variety of configurations to meet specific applications. The dual mechanism is optimized to provide maximum bearing life, superb reliability and can be custom engineered to fit existing envelopes. These units set the standard for performance you’ve come to expect from Simplicity and the proven designs have been utilized in hundreds of applications.

Simplicity’s DM Series incline screens are uncompromised workhorses designed for heavy-duty scalping, intermediate sizing or finished screening of virtually any material. The DM Series twin shafted dual mechanism delivers rugged reliability for large, heavy production demands with a variety of configurations to meet specific applications. The dual mechanism is optimized to provide maximum bearing life, superb reliability and can be custom engineered to fit existing envelopes. These units set the standard for performance you’ve come to expect from Simplicity and the proven designs have been utilized in hundreds of applications.

terex.com

MAJOR

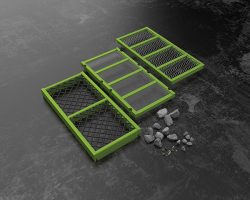

MAJOR offers FLEX-MAT Modular screen media panels. The company’s signature screen media delivers increased throughput by providing more open area than traditional panels. FLEX-MAT features up to 40% more screen capacity than traditional woven wire and up to 50% more than traditional polyurethane and rubber panels, setting a new standard in performance for aggregate, mining and industrial producers. The innovative product’s high-frequency movement makes media an active part of the screening process, improving efficiency compared to static media such as woven cloth or synthetic panels. The modular panels are available in three pattern options for different applications.

MAJOR offers FLEX-MAT Modular screen media panels. The company’s signature screen media delivers increased throughput by providing more open area than traditional panels. FLEX-MAT features up to 40% more screen capacity than traditional woven wire and up to 50% more than traditional polyurethane and rubber panels, setting a new standard in performance for aggregate, mining and industrial producers. The innovative product’s high-frequency movement makes media an active part of the screening process, improving efficiency compared to static media such as woven cloth or synthetic panels. The modular panels are available in three pattern options for different applications.

majorflexmat.com

HAVER & BOECKER NIAGARA

Haver & Boecker Niagara offers the Niagara F-Class vibrating screen for tough applications, such as scalping and classifying ores, minerals, stones, sand and gravel. The vibrating screen includes three screen decks and features an advanced double-eccentric shaft design that’s supported by four high-performance, double-spherical roller bearings. The F-Class is ideal for efficiently screening in situations that require consistent, load-independent performance at constant g-force. Minimal structural vibrations allow multiple screens to be placed side by side in the same building. Cambered decks on the F-Class are equipped with the Ty-Rail quick-tensioning system, which cuts media replacement time by about 50%.

Haver & Boecker Niagara offers the Niagara F-Class vibrating screen for tough applications, such as scalping and classifying ores, minerals, stones, sand and gravel. The vibrating screen includes three screen decks and features an advanced double-eccentric shaft design that’s supported by four high-performance, double-spherical roller bearings. The F-Class is ideal for efficiently screening in situations that require consistent, load-independent performance at constant g-force. Minimal structural vibrations allow multiple screens to be placed side by side in the same building. Cambered decks on the F-Class are equipped with the Ty-Rail quick-tensioning system, which cuts media replacement time by about 50%.

haverniagara.com

KPI-JCI and ASTEC MOBILE SCREENS

KPI-JCI and Astec Mobile Screens multi-frequency screens combine the power of an incline screen with a high-frequency bottom deck; inducing energy into both the box and directly into the media. As fine material touches the screen media at a much greater rate, the probability of separation will increase. With up to three times more revolutions per minute than a conventional screen, your operation will be more productive than ever. These screens operate at a lower angle than traditional high-frequency screens and feature easy-to-use hydraulic screen angle adjustment systems. They also use variable-speed hydraulic vibrators, allowing for optimal screen efficiency.

KPI-JCI and Astec Mobile Screens multi-frequency screens combine the power of an incline screen with a high-frequency bottom deck; inducing energy into both the box and directly into the media. As fine material touches the screen media at a much greater rate, the probability of separation will increase. With up to three times more revolutions per minute than a conventional screen, your operation will be more productive than ever. These screens operate at a lower angle than traditional high-frequency screens and feature easy-to-use hydraulic screen angle adjustment systems. They also use variable-speed hydraulic vibrators, allowing for optimal screen efficiency.

kpijci.com

Print this page