Features

Aggregates

Technology

Equipment spotlight – Screen Media

The newest technology for Canada’s aggregates industry

November 27, 2014 By Rock to Road

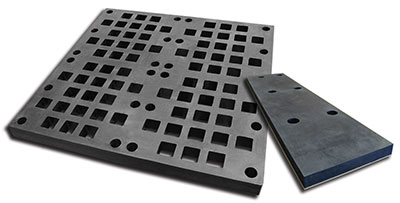

The Armadex product line of high-performance, bolt-down rubber screen

sections and liners from Polydeck Screen Corporation offer outstanding

performance in the most abusive, top deck screening applications.

|

|

Polydeck

The Armadex product line of high-performance, bolt-down rubber screen sections and liners from Polydeck Screen Corporation offer outstanding performance in the most abusive, top deck screening applications. Using a proprietary BIM (Binary Injection Molding) technology, they combine a customized blend of natural rubber with high strength, low alloy steel that results in a product that has shown to outlast competitive products as much as 2-to-1. Screen sections are available up to 48" by 96" in size.

|

|

Powerscreen

Powerscreen, one of the world’s leading providers of mobile crushing and screening equipment, has recently expanded its extensive screen media offering to include 3D Punch Plate. For use in Powerscreen quarrying, mining and recycling equipment, the newest option prevents material build-up, leading to increased machine uptime, and is particularly useful in sizing or scalping operations and in heavy duty screening applications. In addition to the 3D Punch Plate, regular punch plate is also available in mild steel, stainless steel and the latest abrasion resistant metals and can be purchased in a wide range of apertures in either round, square, rectangular or hexagonal holes to suit all applications.

|

|

Sandvik

Sandvik offers a full lineup of modular, tensioned, pre-tensioned and self-supporting screen media solutions, both rubber and polyurethane. The screen media are built for specific applications throughout the quarry screening process, including primary, secondary, intermediate and final screening. Screen media solutions are available for both wet and dry applications depending on the demands of the quarry.

|

|

McLanahan

McLanahan offers a specialized screen media and mounting system used in their line of dewatering screens. The McLanahan Type 02 media was specifically designed to carry heavy loads while resisting the severe slurry abrasion that can destroy conventional mounting systems. McLanahan also provides custom moulds applied to each customer to solve wear issues and increase screen media life.

|

|

Elrus

Elrus provides five EL-Xtra screens for replacement screen media for the aggregates industry. The “D” series is ideal for exact sizing of passing material while increasing screening efficiency. The “T” series is designed for larger sizes and is reinforced for heavier loading and higher energy impact materials. The “S” series delivers maximum throughput and is ideal for the removal of fines, which produces a cleaner retained product. The Harp series is designed in a standard piano wire screen style with maximum open area. The HL-Series The Clean Slot series is designed with alternating straight and crimped wires in a slotted screen design with an elongated opening.

|

|

Metso

Whatever the application, there is a Metso screening media solution to meet your needs. This extensive range of screening media includes synthetic and wire media designed to offer maximum productivity without compromising quality. The unmatched range meets all needs in terms of cost, availability, module sizes, functions and more.

|

|

Weir Minerals

Our next generation modular system, Snapdeck 2000 modular screen, raises the bar on time savings and high-capacity performance. It provides increased open area, pinless panel changeout and the maximum in cost-efficiency. Easy snap button-down installation makes modular retrofits and replacements easy. Modular screens are available in a variety of urethane or rubber compounds.

|

|

W.S. Tyler

Ty-Wire from W.S. Tyler combines the durability and longevity of polyurethane with the greater open area of woven wire cloth for a highly efficient screening alternative. Comprised of high-carbon woven wire encased with an engineered grid made of polyurethane composite, Ty-Wire is able to withstand high temperatures and high tonnages, while offering a wear life of up to six times longer than wire cloth. The top of each opening is narrower than the bottom, preventing plugging of near and oversize material.

|

|

Major Wire

Major Wire’s Flex-Mat 3 High-Performance Screen Media helps aggregate operations increase screen capacity and material throughput while reducing downtime. It employs independently vibrating wires that increase product throughput by up to 40 percent over woven wire or polyurethane and rubber panels by increasing open area and eliminating blinding, pegging and clogging.

|

|

RhinoHyde Products

RhinoGrid hook screens are available in many opening sizes from .65 mm slotted to 4” square openings. Choice of material is dependent on the application and we have various materials to fit your requirements.

Print this page