Products & Equipment

Pits & Quarries

Metso DNA expands to mining and construction

November 29, 2011 By Aggregates & Roadbuilding

|

Nov.

29, 2011 – Metso DNA recently introduced new control applications to make

energy, pulp and paper – and now mining and construction industries – more

user-friendly, productive and profitable.

|

Nov.

29, 2011 – Metso DNA recently introduced new control applications to make

energy, pulp and paper – and now mining and construction industries – more

user-friendly, productive and profitable.

Metso

is the first to introduce embedded machine condition and runnability monitoring

within process controls. Also on offer are new control applications, such as

winder controls, power plant turbine controls and machine condition monitoring.

Scalable

Metso DNA automation systems adapt to diverse mining and construction industry

needs, from single-machine controls to plant-wide automation and information

management systems.

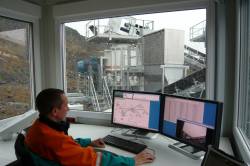

One

product, a new crushing plant control room solution, connects crushers and

screens, ensuring the effective management of the entire plant from a pleasant

and safe control room. Automatic controls stabilize the process and allow the

operators to monitor the plant as a whole.

Machine

condition monitoring has been developed for the condition monitoring of

rotating machines such as flue gas fans, feed water pumps and turbines.

With

this system, says Jaakko Oksanen, product manager Metso, the user receives

process data in real time and retrospectively from the same user interface.

“The user can easily access all the data collected during his/ her absence, for

example, over the weekend.”

Metso

DNA is a single automation system for all functions – process, machine, drive

and quality controls. It also covers information management, and mechanical and

field device condition monitoring. Metso DNA is scalable from a single

stand-alone controller to mill and plant-wide systems in global organizations.

Post-1988 systems are easily upgraded.

Print this page