Products & Equipment

Aggregates

Technology

Astec put on quite the show at this year’s World of Asphalt/AGG1 Aggregates Academy & Expo

April 2, 2024 By Rock To Road Staff

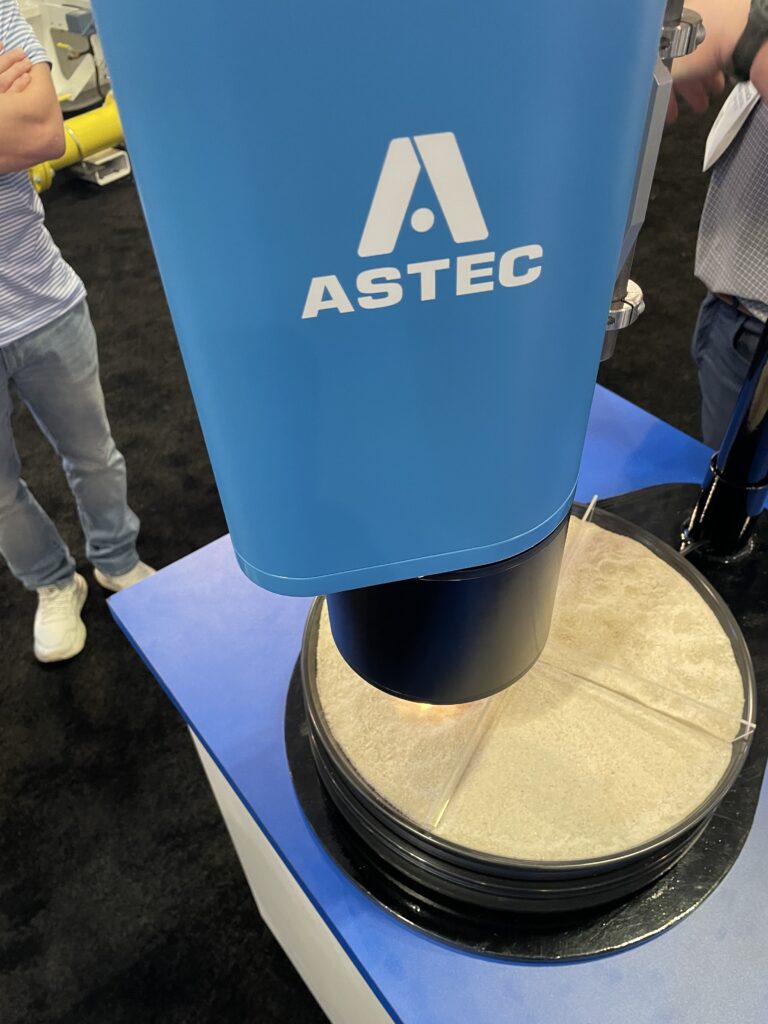

Astec Industries believes its IntelliPac Moisture System will revolutionize asphalt production. Photo: Mike Lacey

Astec Industries believes its IntelliPac Moisture System will revolutionize asphalt production. Photo: Mike Lacey NASHVILLE, Tenn.– Astec Industries unveiled a number of new technologies at this year’s World of Asphalt and AGG1 Aggregates Academy & Expo.

The show ran from March 25 to 27 and set new records in both attendance and square footage. More than 15,800 industry professionals took in the event, which featured more than 440 exhibitors and 120 educational sessions.

Astec Industries used the show to highlight some of the latest technology it has coming to the market.

Vari-Frequency Screen Technology

Astec boasts that its new Vari-Frequency technology will eliminate screen cloth blinding.

According to Astec, the bottom deck of a screen box will be equipped with its new technology. The design incorporates supportive cables that prevent plugging and blinding, the company explains, which will increase capacity, and decrease maintenance and cleaning costs.

“Anyone out there that has ever run a screen box of any type, and there are multiple types of screens out in the industry that have experienced the issue of blinding at some stage and this technology that we have on the lower deck helps reduce that blinding and eliminate it in most cases,” explains Stephen White, aggregate processing expert with Astec Industries.

Astec states that key highlights of the new technology are:

- Uses standard, side-tensioned screen wire cloth.

- Functionality is achieved through a deck that generates multiple vibrations throughout the length of the screen.

- Self-cleaning technology eliminates need to for manual cleaning.

- Does not require external power source.

- Screen has common interface points with other low-profile screens for easy replacement.

The technology is expected to be available on the market later this year.

IntelliPac Moisture System

One of Astec’s more popular pieces of new technology at this year’s show was the IntelliPac Moisture System. Astec states the system will revolutionize asphalt production as it offers an unparalleled look at aggregate moisture levels.

Advanced features also provide operators with real-time data and insights, which the company notes allow for precise adjustments that can result in significant cost savings.

“This is a fully integrated system to monitor your moisture control. This unit is doing it in real time. It also has a health diagnostic to make sure that its running at the performance it needs to be,” explains Astec’s Aaron Schoolfield.

“It’s going to have control authority on your plant … So, when it sees the moisture change in value it will adjust accordingly.”

Those real-time moisture values provided by the system enable operators to make on-the-fly adjustments. Astec notes this level of visibility into aggregate moisture allows for more precise addition of liquid asphalt cement to ensure optimal asphalt mix consistency. As well, operators can fine-tune burner operations based on real-time moisture values. This will maximize energy efficiency and reduce operational costs.

The system also has comprehensive data logging so virgin aggregate moisture levels can be tracked and analyzed for historical trends.

The technology generated quite a bit of interest from those who attend the show.

“(There is) a long list of leads from first five hours of launch. The first few hours it’s been very popular,” says Schoolfield.

Operator Environmental Awareness System

Astec is combining artificial intelligence with software to improve safety features for heavy equipment.

The Operator Environmental Awareness System software will stitch together different camera angles to provide a machine operator a 360-degree view of what is around their equipment. However, it also does much more.

“It will segment between if you’re looking at an obstacle or a person,” explains Astec’s Tim Lenger. “So, with that 360 view and being able to decide what’s a human and what’s not, it will allow the machine to back up to obstacles a little closer than it can now.”

Astec plans on having the technology on the market in the fourth quarter of 2024.

SmartEdge Joint Detection

Astec’s new laser technology was developed for the F-series Roadtec Pavers. SmartEdge will provide a precise 3D model of a concrete or asphalt vertical edge. This will allow for precision joint matching during paving, and ensure improved longitudinal joints and correct overlap.

Print this page