News

Projects

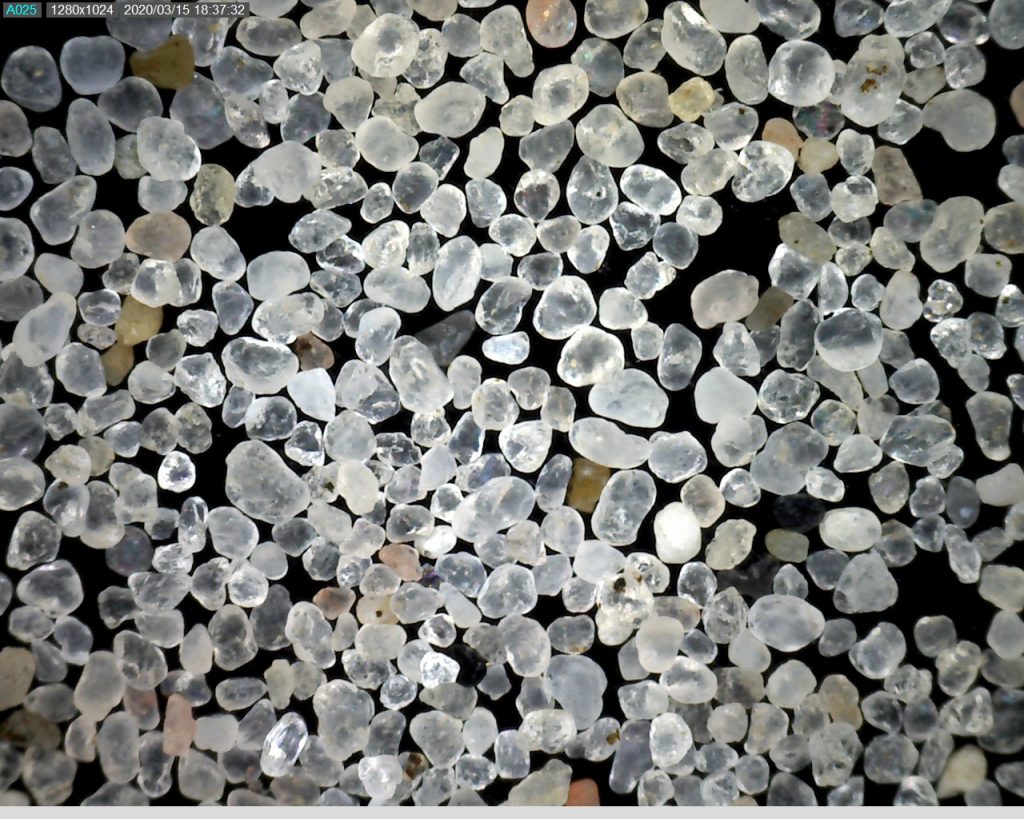

Aggregates

AMI Silica prepares for joint venture green silica sand facility in Alberta

The estimated 800,000 tonnes per year silica sand facility should provide products that serve various customers in the energy, construction and environmental sectors.

September 30, 2020 By Jay Koblun

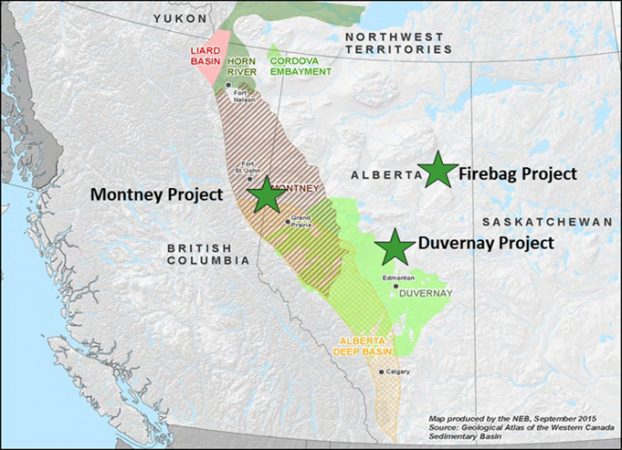

A new Tier 1 silica sand facility in northeastern Alberta is set to be in operation the first half of 2022. AMI Silica signed a term sheet with an international industrial partner to pursue the Duvernay Silica Sand Project as a joint venture initiative. AMI Silica is a division of Athabasca Minerals.

Finney says the joint venture aims to co-develop and operate one of the greenest silica sand facilities in North America.

Tanya Finney, director, investor and stakeholder relations at Athabasca Minerals. Photo courtesy of AMI Silica

“We say it will be one of the greenest silica sand facilities because we are going to use our partner’s industrial utilities. They have processed water we can use for our wash and dry facility,” she says. “Our silica sand facility is just that, a wash and dry facility, there’s no processing in it. We are not taking the sand or rock and trying to process it down into silica sand. It’s a really clean operation. The processed water helps us mitigate any dust and helps us clean the sand and get it ready for distribution.”

Finney also said the silica sand, often referred to as frac sand, located in Alberta and northern British Columbia is benchmarked to Wisconsin sand. Wisconsin sand is imported into Canada via rail.

“What we’re trying to do is displace some of that sand. We want to utilize the resources here more efficiently via rail or trucking, as opposed to the distance from Wisconsin,” she says.

AMI Silica’s geological partner will be announced after AMI Silica completes its Front-End Engineering Development (FEED) period, scheduled to be completed the first half of 2021.

“FEED usually stands for Front-End Engineering Design and we’ve chosen to use development over design because we already have a design,” says Finney. “In that stage we will look at our design schedule; how we build it, how much it will cost, and how much capacity we can put through the facility. That’s what is done in the FEED period. Afterwards we go into construction and break ground, get regulatory approvals for the building, facility and sand deposit. Then we can start on commercial operations.”

During the FEED period, a number of funding alternatives will be assessed, including project financing as well as green grant and green bond opportunities. The aim is to minimize shareholder dilution while maximizing long-term shareholder value. The project is set to offer long-term employment, support for local businesses, and a more substantial, diverse tax base for the province and local economy.

During the FEED period, a number of funding alternatives will be assessed, including project financing as well as green grant and green bond opportunities. The aim is to minimize shareholder dilution while maximizing long-term shareholder value. The project is set to offer long-term employment, support for local businesses, and a more substantial, diverse tax base for the province and local economy.

Robert Beekhuizen, CEO of Athabasca Minerals and president of AMI Silica, said the project brings economic and environmental benefits to Alberta.

“We are excited about the strategic merits of this project, and to have attracted the interest of a world-class Industrial Partner. In terms of market economics, the planned operation will mitigate western Canada’s reliance on imported American sand by introducing Alberta-based, premium domestic sand at improved prices,” said Beekhuizen. “Our green initiatives will minimize the environmental impact and carbon footprint.”

AMI Silica said these are some of the unique synergies the facility will provide:

- Industrial land suitable for construction.

- Access to industrial utilities, including process water, power and heat recovery opportunities that bring distinctive environmental benefits.

- Access to transportation infrastructure that will broaden the economic distribution of product across Alberta and into Northeast British Columbia.

- Additional premium domestic sand deposits located in close proximity to the proposed industrial location, clear of residential areas.

- Long-term employment, support for local businesses, and a more substantial, diverse tax base for the province and local economy.

Sand drill. Photo courtesy of AMI Silica

The estimated 800,000 tonnes per year silica sand facility should provide products that serve various customers in the energy, construction and environmental sectors.

“In Alberta about three million tonnes are imported into Canada each year. Our expected capacity is 800,000 tonnes per year for the next few years and we expect to optimize our production and get up to one million tonnes per year,” says Finney. “That takes out a nice percentage of that imported sand. In Canada about two million tonnes of domestic sand is used. But its Tier 2 sand. Not all operators can use that sand, which is why we get silica sand from the U.S. imported in.”

Finney stressed that a strategic plan around community engagement is one of the top priorities.

Print this page