Products & Equipment

Pits & Quarries

Telsmith to showcase 44SBS cone crusher at Hillhead 2018

May 16, 2018 By Telsmith

Telsmith 44SBS cone crusher

Telsmith 44SBS cone crusher May 16, 2018 – Telsmith, Inc., a leading manufacturer of mineral processing equipment, will exhibit at Hillhead 2018 in Buxton, U.K. from June 26 to 28.

Telsmith, Inc. will be one of several Astec companies included in the lineup for the Astec Aggregates and Mining Group Stand: CE11.

To showcase the Telsmith promise, “The Extra Mile Isn’t Extra. It’s Included,” that was launched at AGG1 in March of 2018, the team will explain the 44SBS cone crusher benefits and discuss safety and uptime features as well as their concept to completion services.

The Telsmith 44SBS cone crusher is specifically designed for large, extra coarse feed material ideal for secondary and tertiary circuit positions in mining, aggregates, and crushed stone production.

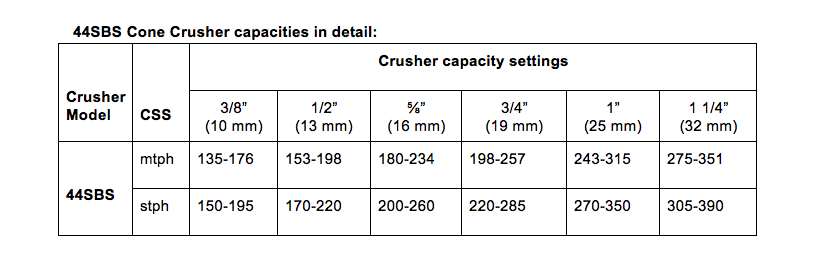

Available in stationary units as well as in portable configurations, the 44SBS 223.71 kW (300 HP) cone offers output capacities ranging from 135 to 351 metric tons per hour or 150 to 390 short tons per hour depending on desired final output size and provides up to a 200mm (8-inch) feed size.

Safety and uptime are engineered into 44SBS cone crushers by adding the Telsmith exclusive, patented overload protection design which limits the amount of force the cone crusher needs to absorb when it encounters overloads or tramp metal – providing the best protection for internal parts. This design has proven to save operations thousands of dollars in unexpected repair costs.

The 44SBS allows for quick and safe chamber clearing should you have a power failure or tramp metal in the crusher. With a push of a button, the 44SBS crusher clears in minutes, avoiding hours of downtime. Operators simply flip a switch from the “crush” mode to the “clear” mode, and the upper frame is lifted vertically allowing the material to easily and safely fall through the crusher bringing you safely back in production with a minimal loss of time and profitability.

Zero Maintenance Anti-Spin System includes a small hydraulic motor that is attached to the shaft preventing the head from spinning when running with intermittent feed. No adjustments, resetting, or regular maintenance schedules are needed.

The anti-spin system provides longer manganese life and produces a more cubical product.

Telsmith, Inc. provides a full range of minerals processing solutions to the aggregate, mining, industrial, and recycling industries with cone crushers, jaw crushers, vibrating equipment, portable plants, track plants, as well as full-scale modular processing facilities. Solutions from Telsmith include product lifecycle support with parts availability and factory trained service technicians. For more information about Telsmith, please call (262) 242-6600 or visit www.telsmith.com.

Print this page