Features

Columns

Education

On the Straight and Level

Aggregates & Roadbuilding talks to the ‘Big 3’ about what they offer, what’s new and what’s ahead.

June 13, 2011 By Treena Hein

Roadbuilding software has come a long way in the last few years – and is evolving every day.

Roadbuilding software has come a long way in the last few years – and is evolving every day. The “big players” in software development are constantly making additions and improvements, and releasing new versions of their products every six months or so in a never-ending quest to make roadbuilding easier and more cost-effective. We’ve taken a look at what’s new and what’s available in this issue, and in the next, we’ll talk to contractors who are using various brands of software to cover ease of use, applications, training issues and more.

Topcon

A new version of Topcon Positioning System’s SiteMaster (an integrated design, surface modelling and construction survey software package) was released in late May. “Our software is different than any other in the market in a couple of ways,” says Mark Larranaga, software business development manager at Topcon’s Construction Division. “One, we can run the software on a USB key without the need to load the program on a computer. This gives customers great flexibility to share the software amongst users or computers.”

Larranaga says secondly that with their system, a project (including linework, points, digital terrain model (DTM) and alignments) can all be contained in one easy-to-upload file.

|

|

| Topcon’s SiteMaster is an integrated design, surface modelling and construction survey software package. (Photo courtesy of Topcon) Advertisement

|

One feature that stands out in Sitemaster’s roading module (called “Roads View/Editor”) is its interactive three-panel view, which simultaneously displays alignment, profile and cross section. “It includes powerful string and template design that can handle an unlimited number of strings for design of simple roads to multilane highways,” notes Larranaga. “A curve-length calculator is also provided to simplify vertical curve design.”

Topcon recently built a separate pull-down menu option that provides access to all the steps it takes to build road models, which saves time. “In this menu, there are some exciting automation tools to clean up drawings and elevate 2-D to 3-D,” adds Larranaga. Another feature is one-click DTM creation. “The formation of the triangles is a one-button operation, with nominated break lines being incorporated into the model upon triangulation,” he notes. The program provides many options for editing, deleting triangles and viewing the surface in 3-D, with multiple surfaces supported.”

SiteMaster also recently added a resurfacing module to the software, part of its RTP-300 profiling system. “You can do things like process data using roading functions into a resurfacing design view, graphically design optimum resurface levels for paving and road rehabilitation, export road rehabilitation strings, and generate pavement volume reports,” Larranaga says. In addition, in order to move contractors towards a fully integrated digital job site where all data is shared, Topcon has linked SiteMaster in the office with SiteLink in the field. “This allows users to do things like update a file for a machine control system, monitor machines for productivity, or troubleshoot a system remotely,” notes Larranaga.

Trimble

Trimble’s Business Center – Heavy Construction Edition (HCE) allows users to facilitate the reconstruction of road models from the parametric information used by the engineer to create the road. HCE puts the emphasis on the efficient management of data for multiple field crews operating on a single job site, says Jamal Mohammed, mid-Canada sales manager at Trimble distributor SITECH. “Using HCE, contractors can import, review and analyze digital design information and easily assign, manage and track that information through the lifetime of a construction project,” he says. HCE also provides graphical visualization of design data and field measurement records, automated routing of data to and from the office (with automatic detection of discrepancies), material volume computations and high-quality, easily understood reports.

|

|

| Working with Trimble’s equipment in the field. (Photo courtesy of Trimble) |

HCE interfaces with all common road modelling programs and design files. “HCE can also recreate digital data and 3-D models quickly and efficiently using the information provided on engineering plans,” says Mohammed. “At the bid stage, HCE allows the contractor to rapidly import or recreate alignment geometries, digitize cross sections and compute 3-D surface models to quantify materials quantities needed for a project,” Mohammed notes. Users can also design temporary files pertaining to site access, haulage routes and retention ponds, making updates in order to react to unexpected ground/weather conditions.

Based on customer feedback, Trimble is fast developing HCE into a powerful software suite that allows contractors to efficiently manage site and highways earthworks, grading and finishing operations. “Four versions of the HCE highway edition have been released over the past 18 months,” notes Mohammed. During the first year of purchasing the software, the updates are at no charge. After the one-year period, if the customer continues to pay a minimal annual “software support fee” ($700), all software for that year is free.

If not, after the first year of purchase, “major upgrades” are chargeable. “Key improvements in these versions include a “corridors modeling” capability that provides a quick and simple way to construct finish, and subgrade surface models from plan or imported design data,” he adds. “There is now also a new alignment-based surface model designed and optimized to work with alignment-based information rather than irregular site information.” Cross section review and editing tools for cross section data (or nodes within a cross section) have also been added.

“In addition, there is now a surface densification tool for road information, accurate enough to build the surfaces to design tolerance specifications,” says Mohammed. “With this improvement, users can also accurately interpolate between cross sections to form a surface model that meets design tolerances.” The latest version also features 3-D visualization tools that visualize and analyze design models to inspect for defects prior to taking surface models into the field, and 3-D editing tools for correcting defects. A flagging system for imported design information instantly highlights and quantifies imported or created surface model defects typically encountered, such as crossing breaklines.

Leica Geosystems

Leica Construction Office (LCO) was released in North America in September 2010. This software package empowers contractors to take over data flow for their projects, says Nick Guadagnoli, product marketing manager for North America. It allows the users to work with reference data in industry standard formats such as .dwg, .dxf and LandXML, as well as view design data in 3-D to verify the data before they bring it to the field. “LCO allows a user to convert 2-D data received from the engineer into 3-D data that can be used on their machine control systems or construction positioning equipment,” says Guadagnoli. “It also gives the user options on how they design road jobs, such as using a HAL and VAL, a HAL plus a surface and also support of roading templates. Users can create complex road models that feature super elevations, spirals, and variable side slopes.”

Guadagnoli says LCO stands apart in terms of ease of use and an unmatched user interface. “We provide dedicated routines for commonly performed functions such as import/export, surface creation, transformations, and creation of reference data to be used in the field – all of which empowers the contractor to do more in house,” he notes. “We’ve developed the software in parallel with our machine control and construction positioning solutions, which means users work with common data formats and structures. This drastically reduces the amount of data management time and manipulation that a professional data manager would otherwise have to do.”

In addition, the product has been developed around a core platform, with supplemental modules that contractors can evaluate and purchase according to their needs. “This reduces a contractor’s initial investment and also guarantees they pay only for functions they are actually going to use,” Guadagnoli notes. “The platform can be used as a simple import/export tool to prep data to be moved to Leica’s machine control and positioning products, or scaled all the way up to a full-blown road modelling software package with full machine control applications.”

Topcon’s Larranaga believes that in the future, the roadbuilding software industry will continue to focus on software enhancements to complete a total solution. “Seamless integration of hardware and software will be the key to the success of a company,” he says. Trimble’s Mohammed predicts that future software packages will be developed to incorporate schedules and cost. Guadagnoli says Leica’s LCO’s ongoing development is focused on making the product even simpler to use and integrating it even more seamlessly with the company’s hardware and other software platforms. “It is a very exciting time for the construction industry,” he notes. “Contractors are now able to reap the benefits of using tools exactly suited to their needs.”

The Hardware Component

Great software also requires suitable hardware, and all three of the companies we talked with have equipment that is designed to work with their technology.

|

|

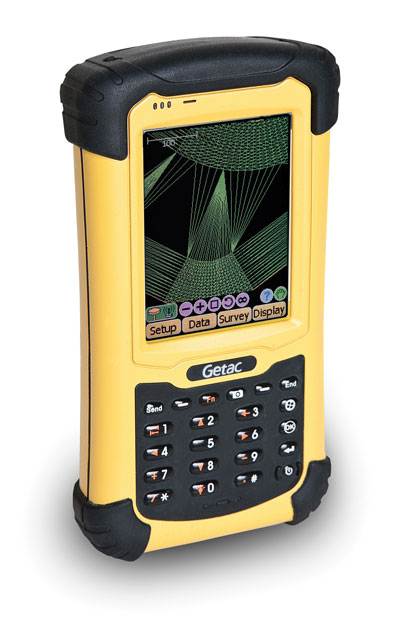

| Topcon Positioning System’s FC-236 handheld device is used to run Pocket-3D software (which integrates with the use of ‘SiteMaster’ back in the office). |

All companies provide rugged hardware options that allow data collection, management and transfer from the roadbuilding site. Topcon Positioning System’s FC-236 handheld device is used to run Pocket-3D software (which integrates with the use of ‘SiteMaster’ back in the office). The FC-236 meets military standards and has a IP67 rating against water, humidity, sand and dust. “It features Bluetooth wireless and 3.5G cellular connectivity, with a high sensitivity GPS Receiver and a 3MP autofocus camera,” says Mark Larranaga, software business development manager at Topcon’s Construction Division. “Its 3.5” touch screen is sunlight-readable,” he adds. The Pocket-3D software allows contractors to check grade, cuts and fills, layout points and survey the jobsite. “Cut/fill information is constantly displayed on the screen,” notes Larranaga, “and with our system, one person can now control grade over the entire project for multiple machines.”

For using its Business Center – Heavy Construction Edition (HCE) software, Trimble recommends using its handheld (called the TSC3) and the Trimble Tablet. “With the TSC3, you can survey real-time quantities with the integrated camera and do automatic GPS geotagging as well,” says Jamal Mohammed, mid-Canada sales manager at Trimble distributor SITECH. “Most importantly, it allows web collaboration with the people in your office.” The TSC3 also features a QWERTY or ABC alphanumeric keypad, compass, extended battery life, and a large, high resolution, full VGA touch screen display.

The Trimble Tablet is a rugged, versatile and fully connected handheld computer that incorporates a cellular modem, laptop, GPS and controller. “It allows construction professionals to make design changes in the field, connect to the office for on-the-spot approvals and communicate changes to field crews,” Mohammed notes.

Leica Construction Office (LCO) software is used in the field with the company’s ‘Viva Field Controller’ CS10 or CS15 handheld devices. “Leica’s CS10 and CS15 are designed for extreme environments,” says product marketing manager Shannon Hixon. “They come with an IP67 rating against water, humidity, sand and dust, with an operating temperature range of -30 to 60° C.” The CS devices also feature a tactile, fully illuminated, rubber keypad (numeric on CS10, alphanumeric QWERTY on CS15), a two-megapixel camera, and a colour VGA illuminated touch screen. CS users have a choice of two connector modules, with data storage available through the use of an SD Card, CF Card or USB memory stick.

Print this page