Products & Equipment

Pits & Quarries

McCloskey debuts V80 vertical shift impactor

March 20, 2013 By Andrew Macklin

March 20, 2013, Peterborough, Ont. – The McCloskey

March 20, 2013, Peterborough, Ont. – The McCloskey

International V80 Vertical Shaft Impactor will make its North American

debut at The World of Asphalt/AGG1 show in San Antonio, Texas from March

19 to 21, 2013.

The McCloskey V80 (VSI) has been designed for producing high specification sealing aggregates, a high proportion of fines required for main roads/road-base, or manufactured sand. This heavy duty track mounted Vertical Shaft Impactor features a host of user friendly features, and reflects McCloskey’s commitment to reliable and durable equipment.

The first North American dealer to stock the V80 will be McCourt and Sons of LaGrange, Texas.

“We have had enormous success with the McCloskey crusher lines including the jaw, cone and impactors,” said Paul McCourt, owner and president of McCourt and Sons Equipment Inc. “Carrying the VSI product will allow us to offer even more options to our customers to help them grow their business – no matter what the application.”

The V80 has a CEMCO Turbo T-80 VSI crusher, and a powerful 430 Hp C13 CAT engine. The sturdy I-beam plate fabricated chassis construction lends itself to the most heavy duty applications, along with its long-wearing Hardox hopper sides adding to is durability and strength.

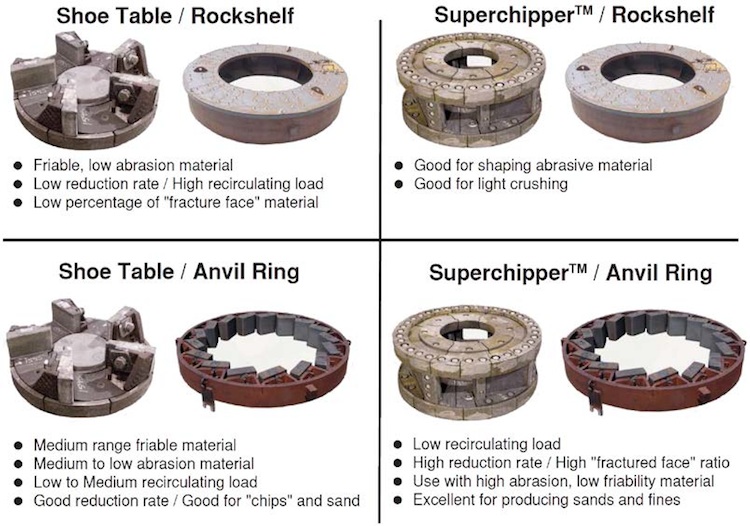

The McCloskey V80 offers a number of internal rotor/rockbox/anvil configurations that are suited for all applications, including:

The V80’s feed rate is controlled via control panel, remote control or fully automatic regulation via feedback from the VSI. The main conveyor has a large stockpile capacity (10’ – 8”) as a result of the standard extended 42” conveyor, and the large access between crusher discharge and the main conveyor feedboot. The V80 also features an integrated hopper with folding rear door.

As with all McCloskey equipment, ease of maintenance is a strong advantage for the V80. The Control Panel is user-friendly and has machine diagnostics that can drastically reduce downtime for maintenance. The open chassis design adds to the ease of maintaining the V80, as well as the hydraulic raise/lower lid on the crushing chamber.

With the advantage of McCloskey’s integrated and highly efficient hydraulics, better fuel economy is realized. The V80 boasts a fast setup time, due to its folding hoppers and conveyors. Easy to move from site to site, the V80 has transport dimensions of 52’ – 7” (16.02m) long, 9’ – 6” wide (2.9m) and 11’-2” (3.4m) high weighing in at 85,980 lbs. (39,000 kgs).

With additional options like a roll-in bogie system, main conveyor variable speed control, Interlock systems, hopper extensions, and a metal detector to protect the VSI along with robust standard safety features, the V80 is high performance and productive.

About McCloskey:

McCloskey International Ltd. designs and manufactures innovative crushers, impactors, trommel screeners, vibrating screeners, feeders, stacking conveyors and picking stations. Since 1985, McCloskey International has been exceeding customer expectations with reliable, durable and high performing products. McCloskey equipment is used by topsoil producers, landscape contractors, composting facilities, waste management and recycling operations, aggregate producers and mining and quarry operators to help achieve profitable volumes.

For vehicle specifications and more on McCloskey International Ltd. click here .

Print this page