Features

Liebherr unveils new tech and innovations at CONEXPO/CON-AGG

March 24, 2020 By Jay Koblun

Liebherr created 3,000 new jobs over the financial year, bringing the total number of Liebherr employees to 48,000 worldwide. Photo: Jay Koblun

Liebherr created 3,000 new jobs over the financial year, bringing the total number of Liebherr employees to 48,000 worldwide. Photo: Jay Koblun Andreas Böhm and Peter Mayr started CONEXPO/CON-AGG off with updates from the company and information on its latest equipment and tech innovations announced at the show.

Böhm, Liebherr German manufacturing group’s CFO, and Mayr, managing director, shared from the Liebherr booth on Mar. 10, in Las Vegas, Nev.

“There are all kinds of wonderful things to see and do at CONEXPO, so we’re grateful you chose to stop by our stand,” said Böhm.

Böhm said 2019 was a successful year financially for the company.

Liebherr created 3,000 new jobs over the financial year, bringing the total number of Liebherr employees to 48,000 worldwide. Photo: Jay Koblun

“Overall turnover of over 11 billion Euro was a new record for the company, making it our third record year in a row,” he said. “Compared with the previous year, we enjoyed a double-digit increase in turnover. These figures are quite impressive as the International Monetary Fund’s research showed global economic growth slowed to 2.9 per cent in 2019.”

Another area of growth was Liebherr’s headcount. The company created 3,000 new jobs over the financial year, bringing the total number of Liebherr employees to 48,000 worldwide.

Böhm stated the company is looking forward to another positive year.

“We’re expecting stable to slightly positive sales development in 2020. The international Monetary Fund has forecasted economic growth to ride 3.3 per cent, with growth in emerging and developing countries expected to increase to 4.4 per cent. This bodes well for our continued focus on modernizing company locations and intensifying the Group’s global market presence,” he said.

Mayr presented on several new innovations Liebherr is bringing to North America.

“The earthmoving equipment and material handling product area is an important one for Liebherr USA,” said Mayr. “We have increased out footprint, just covering a few states on the east coast to almost one hundred per cent coverage today. We hope to continue to expand I 2020 with the equipment and innovations we are presenting today.”

Here are some of new machines and tech announced:

LH 30 M Industry Litronic and LH 60 M Industry Litronic material handlers

- Available in the Final Tier 4 and Stage IIIA (compliant) exhaust emissions standards

- Operating weight LH 30 M Industry Litronic: 58,400 – 64,200 lb (26. 5 – 29. 1 t) / engine output 140 kW / 188 HP

- Operating weight LH 60 M Industry Litronic: 121,300 -134,500 lb (55 – 61 t) / engine output 190 kW / 255 HP

A 922 Rail Litronic

A 922 Rail Litronic. Photo: Liebherr

Available in both the Final Tier 4 and Stage IIIA (compliant) exhaust emissions standards. The A 922 Rail is suitable for use on railway tracks and for road construction and is fast thanks to the mobile undercarriage. A rail travel drive is mounted on both sides of the undercarriage. When entering the rails, the rail travel drive lifts the tires to rail height. The inside wheels of the dual tires ensure travel of the excavator on the tracks.

- Operating weight 45,000 – 51,600 lb (20. 4 – 23. 4 t)

- Can be operated either on road or rail

- Decades of experience in developing and producing railroad excavators

Redesign: LRB 355 piling and drilling rig

Liebherr LRB 355 piling and drilling rig. Photo: Liebherr

The overall design of the LRB 355.1 puts special attention on the handling of the machine—both on and off the jobsite. For transportation, the crawlers can now be removed from both types of undercarriage. This reduces the maximum transport weight by about 30,865 lbs (14 t). To minimize the transport length, the leader can be folded. For the longer leader version with 88.6 ft (27 m), this saves 23 ft (7 m). A further advantage is that the machine can be transported with a mounted leader, sledge and ropes. Thus, the piling and drilling rig can be mobilized even more quickly on the jobsite.

- Available immediately worldwide

- More transport flexibility

- Available with Ground Pressure Visualization, Kelly Visualization and Drilling Assistant systems

- New cabin design

R 926 and R 938 crawler excavator

The R 926 and R 930, is based on a specific platform developed by Liebherr. The R 926 and the R 930 have an operating weight between 28 to 34 US tons (26 and 31 t) and achieve a power of 150 kW/204 hp and 180 kW/245 hp respectively. The backhoe bucket capacities vary from 1.15 m3 to 1.75 m3 on the R 926 and between 1.25 m3 and 2,15 m3 on the R 930. The R 926 and R 930 models are available in stage V and Tier 4f.

- The R 926 is equipped with a Leica geosystem

- The R 938 is on display with a special American design

- Simplified, fast and safe maintenance work for a new dimension of robustness

- Further increased machine power thanks to fundamental redesign of the excavator’s various assemblies

New generation 8 crawler dozers with Operator Assistance Systems

New generation 8 crawler dozers with Operator Assistance Systems. Photo: Liebherr

Liebherr introduced its generation 8 crawler dozers with the new PR 736 G8. Equipped with many new developments for even more operator comfort, excellent grading characteristics and the new standard grading systems, the PR 736 G8 is a do-it-all machine for grading and mining use.

- The first model of the new generation 8 crawler dozers: Liebherr PR 736 G8

- New cabin, rear ripper joystick, climate control – many new features for even more operator comfort

- New electronically controlled Liebherr working hydraulics for fast and precise grading

- Three levels of smart operator assistance thanks to Liebherr OAS – Operator Assistance Systems

Crawler concrete pump 110 D-K

Crawler concrete pump 110 D-K. Photo: Liebherr

Liebherr presented its crawler concrete pump THS 110 D-K which features a maximum concrete output of 133 yd³/h (102 m³/h). The six-cylinder engine complies with the Tier 4f emissions standard and therefore complies with current environmental regulations.

- Concrete pump on crawler tracks with maximum concrete output of 133 yd³/h (102 m³/h)

- Particularly suited for applications with constant relocation on the building site

- Remote control is standard

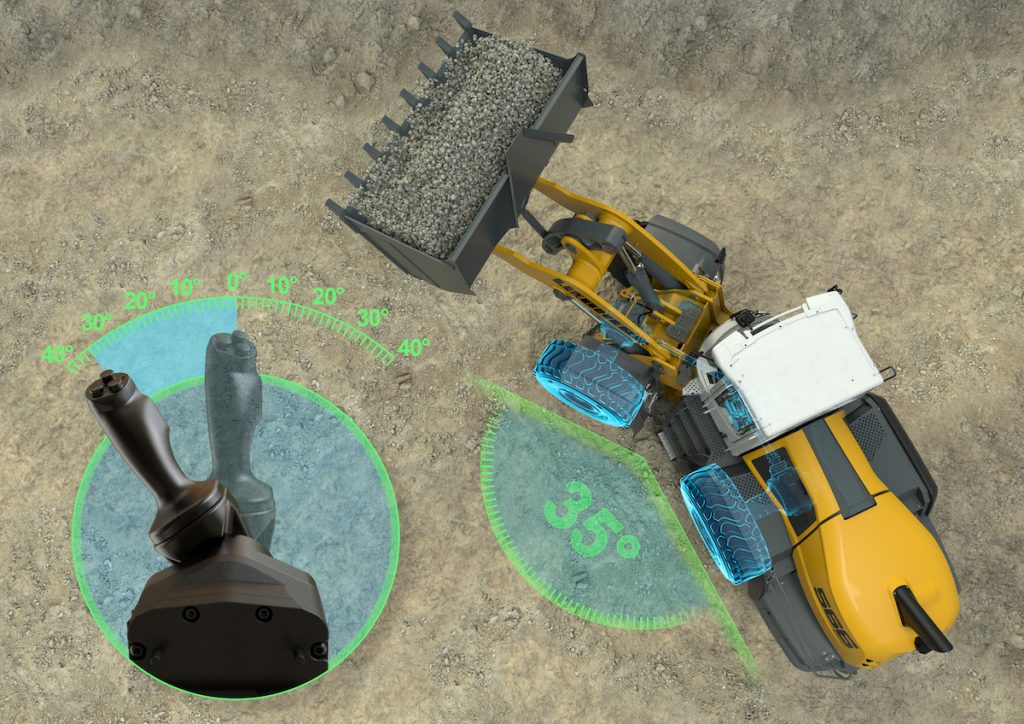

Liebherr wheel loaders with innovative assistance systems and new joystick steering

Liebherr presented four wheel loaders. These include an L 566 XPower which is equipped with numerous new assistance systems. Liebherr will exhibit these assistance systems for wheel loaders for the first time at a trade fair in North America. These include active personnel detection, adaptive working lighting, the integrated tire pressure monitoring system and the weighing system with Truck Payload Assist. The L 566 XPower also has the new joystick steering for wheel loaders.

New partnership

Leica Geosystems is part of Hexagon, a global leader in sensor, software and autonomous solutions. Photo: Liebherr

Liebherr and Leica Geosystems announced the beginnings of a new partnership in machine control solutions. In the digital era, assistance systems like machine control solutions for construction machines will become more and more important. Liebherr relies on the extensive know-how of Leica Geosystems in order to be able to offer customers state-of-the-art complete solution for machine control straight from the factory. Leica Geosystems is part of Hexagon, a global leader in sensor, software and autonomous solutions.

Print this page