Products & Equipment

Heavy Equipment

Danfoss Power Solutions extends PVG portfolio with high-flow proportional valves

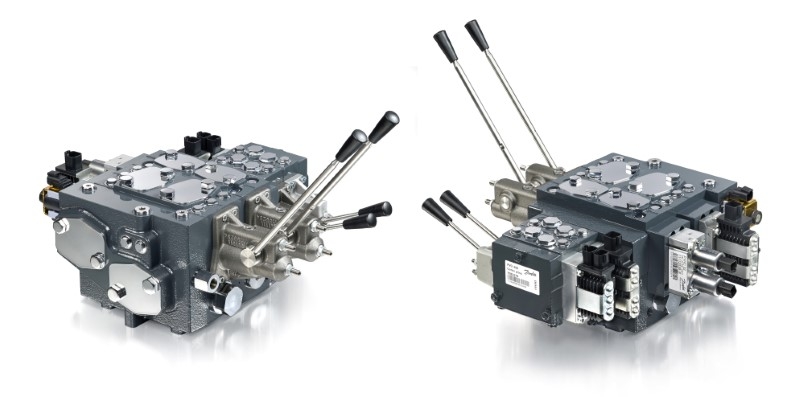

The modular concept used in PVG 128 and PVG 256 simplifies the design process, improving time to market for OEM customers.

March 23, 2018 By Danfoss Power Solutions

March 23, 2018 – Danfoss Power Solutions has added two high-flow proportional valves to its PVG portfolio, expanding its range of low to high-flow capabilities for OEM customers with demanding applications. The PVG 128 and PVG 256 valves are designed to easily integrate with the existing line of Danfoss high performance proportional valves — PVG 16 and PVG 32 — allowing modularity from low to high hydraulic flow within the same valve stack.

These high-flow valves are ideal for use on demanding applications such as large mobile/truck mounted cranes, crawler cranes, ship cranes, winches, drilling machines, etc. where flow and durability is essential. Using the PVG 128 and PVG 256 together with other valves in the PVG family allows OEMs to easily enhance machine performance while improving productivity and lowering energy consumption.

“We designed the PVG 128 and PVG 256 valves to offer as much value as possible to our off-highway OEM customers. They can use these valves to achieve the high flow necessary for their demanding applications, but can combine them with the PVG 32 and PVG 16 for lower flow functions in their machines as well,” said Knud Meldgaard Jensen, Global Product Marketing Manager for Danfoss Power Solutions.

“By keeping the same design concept as the PVG 32 and PVG 16 valves, our customers can easily add and combine the PVG 128 and 256 valves into their custom design,” Meldgaard continued. “The valve modularity ensures OEMs can easily optimize their machine using the entire PVG valve range — saving on space, weight and costs.”

The addition of the high-flow valves extends the range of hydraulic flow within the PVG series up to 300 liters (79 gallons) per minute with the PVG 128 and up to 400 liters (105 gallons) per minute with the PVG 256. A special turbo version of the PVG 256 valve is also available, increasing the hydraulic flow up to 500 liters (132 gallons) per minute.

Modular valve concept

The high-flow valves are designed to work in conjunction with the smaller valves in the PVG portfolio, delivering consistent performance throughout the entire valve range. A total of four different valve sizes offer OEM customers more options — all of which utilize the same electrical and hydraulic interfaces to fit the exact flow needed for each application. The use of common parts within the PVG platform means the high-flow valves can easily be incorporated into existing applications.

Flexible spool options

Danfoss PVG valves offer multiple spool sizes that can be adapted to meet customers’ specific application needs. Available spools are a combination of linear and progressive, meaning the same spool can be used for all configurations with and without LS A/B relief valves.

PVG 128 and PVG 256

Features and benefits of the high-flow valves include:

•High performance and productivity — The PVG 128/256 valves are a pre-compensated valve, and provide the reliability necessary for the most demanding applications.

•Reduced costs and installation complexity — The PVG 128/256 valves can easily adapt to regional fitting standards.

•Optimal productivity and precise operation — The valves offer smooth, load-independent flow control.

•Improved energy efficiency and safety — Individual load-sensing A/B relief valves limit the pressure on each work port of a valve section, reducing material stress.

•A consistent control interface and easy setup — The PVG 128/256 uses the same actuation type as the PVG 32 and PVG 16 valves, meaning it’s already compliant with electrohydraulic actuators, PVHC actuators and PLUS+1.

•Optimized operator productivity — Using the PVE S7 and PVED S5 from Danfoss in conjunction with the PVG 128/256 valve ensures a high degree of precision and repeatability of the valve performance.

•Additional diagnostics — CANbus control lowers the cost of installation and ensures data availability on the machine’s existing bus system.

•Reliable operation — Each valve section has a manual control that allows work to continue even in the event of electrical power failure.

Print this page