Products & Equipment

Heavy Equipment

Caterpillar showcases compact wheel loaders at WOC 2017

January 25, 2017 By Caterpillar Inc.

Photo: Caterpillar Inc.

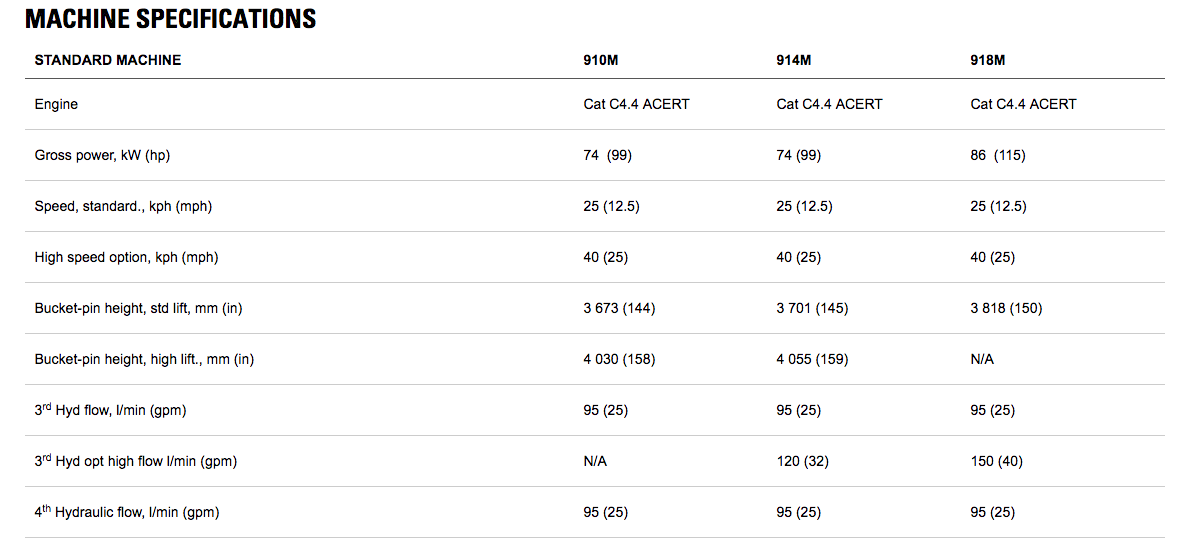

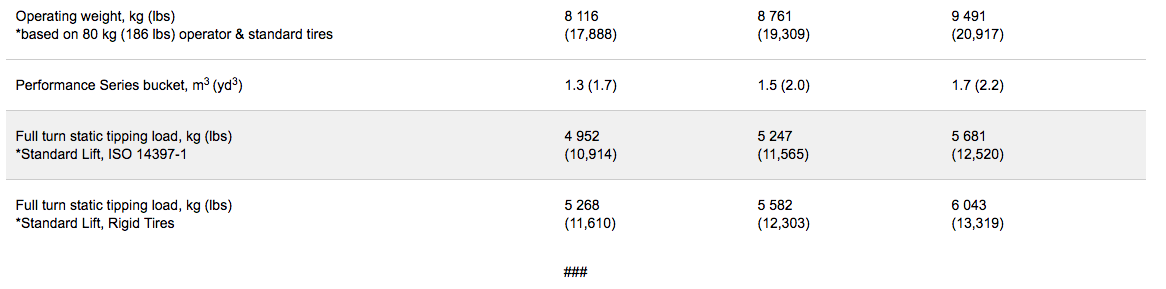

Photo: Caterpillar Inc.January 25, 2017 – The new Cat M-Series Compact Wheel Loaders—910M, 914M and the all-new 918M— were on display at the 2017 edition of the World of Concrete. The wheel loaders build on the success of current K-Series models—910K and 914K— with engineering refinements that include a new, larger-displacement engine that meets U.S. EPATier 4 Final and EU Stage IV emission standards, as well as new options and features that further enhance value, operator comfort, and safety.

The all-new 918M

The new, 115-horsepower (86 kW) 918M expands the Cat compact wheel loader family and has the features to perform efficiently in a range of tasks, whether the job requires the available high-flow auxiliary-hydraulic system to run demanding attachments—such as a snow blower, or standard heavy-duty axles for aggressive performance in waste applications, or the 25-mph (40 kph) high-speed option for roading.

Powerful, efficient performance

A new Cat C4.4 ACERT engine powers the three new M-Series wheel loaders and has a clean emissions module designed to manage itself with no operator intervention or downtime. The module uses a selective-catalytic-reduction system, which requires only the addition of diesel exhaust fluid. The new engine reduces owning and operating costs with standard, fuel-saving features, such as the ECO mode, auto-engine-idle shutdown, and available on-demand cooling fan.

The 910M and 914M feature an intelligent power-management systems that balances performance and fuel efficiency. The system utilizes additional power when the machine senses a higher demand, such as climbing a steep grade or using a high-flow work tool. This on-demand power adjustment provides optimum productivity and hydraulic speed under load.

Operator’s environment

The deluxe cab of the new M-Series models is designed to provide all-day comfort, featuring two side-entry doors, low-effort electro-hydraulic joystick, suspended pedals, tilt steering wheel, and an air-suspended/heated seat that provides an extremely comfortable ride for the operator.

A multi-function, loader-control joystick provides easy, single-lever control of loading functions, as well as transmission and differential-lock controls. The joystick also accommodates controls for two-, three-, and four-valve hydraulic systems, including proportional control of auxiliary circuits.

M-Series wheel loaders also introduce several new optional features designed to enhance productivity, operator safety, and serviceability. An available LED light package includes front and rear LED auxiliary work lights, combined with an optional rearview camera (standard for Europe), ensures maximum visibility for the operator to further enhance job-site safety.

In addition, an optional electronic, soft-touch keypad provides convenient control of most functions and allows operators to program the machine for application requirements and for personal operating preferences. The Implement-Modulation system allows adjusting hydraulic response to one of three levels, and the Hystat Aggressiveness Control provides three levels of shifting smoothness and directional-change response.

Operating features

Rimpull Control, which allows operators to reduce tire slip in poor underfoot conditions, promotes more efficient bucket loading for reduced tire wear and improved productivity. Operator can select among four settings to adjust power reaching the wheels, based on working conditions.

A variable-speed Creeper Control, managed by the left pedal, permits control of ground speed independent of engine speed by functioning as an inching pedal during the first half of its stroke. By thus adjusting the hydrostatic drive system to match ground speed to the task, the engine can operate at high speed for optimum hydraulic performance and precise control of continuous-operation work tools, such as snow blowers and brooms. The Creeper Control and Electronic Throttle work together for optimal work-tool performance and ease of operation.

An optional Ride-Control system utilizes the boom cylinders as dampers when the machine is traveling over rough terrain, yielding a smooth ride and optimum material retention.

For loading applications, the Return-To-Dig feature allows the operator to automatically reposition the bucket to the desired position for the next loading cycle by moving the joystick into a detent position. The Lift Kickout feature stops the loader arms at a pre-determined height when the operator detents the joystick, an essential feature when the machine is working in low-overhead situations.

Loader linkage, work tools

The new M-Series models use the Caterpillar-patented Optimized Z-bar loader linkage, which is designed to deliver both the aggressive digging performance and high breakout forces of conventional Z-bar linkage and the parallel-lift and load-handling capability of a tool carrier.

These models are available with an Integrated Tool Carrier coupler, compatible with legacy Cat work tools, or with the Cat ISO coupler, designed to work with a range of Cat Performance Series buckets, optimized ISO pallet forks, and certain competitive attachments.

The design of Cat Performance Series buckets assists operators in loading faster, to capacity, while retaining material during travel for maximum productivity. High-lift booms on the 910M and 914M provide 14 inches (335 mm) of added clearance in applications requiring adequate lift height, such as loading feed wagons or stacking hay bales.

Fleet management

Cat LINK technologies, such as the Product Link advanced telemetrics system provide a constant stream of wireless information, including location, hours, fuel usage, idle time and event codes. Product Link data are accessed via the online VisionLink® interface and are vital for providing information needed to make timely, fact-based decisions that improve job-site efficiency, increase productivity and lower costs. For added protection, the available Machine Security System now integrates keypad access for engine starting, allowing protected digital access to the ignition without a specially designed key.

Print this page