Features

Pits & Quarries

Roads & Paving

How equipment and training is evolving to meet a changing market

April 22, 2021 By Jay Koblun

CM Labs held its Virtual Tradeshow from April 21 to 22. Photo: John Deere

CM Labs held its Virtual Tradeshow from April 21 to 22. Photo: John Deere Curtis Leconte, project manager of operator training at John Deere presented its latest equipment innovations and how to use simulation to train on new technologies at CM Labs’ Virtual Construction Tradeshow on April 21.

Dedication to Innovation and Solutions

Leconte has been with John Deere for more than 15 years and said John Deere is in his blood. Today John Deere employs more than 60,000 men and women worldwide and manufactures several models o the following equipment.

- Articulated dump trucks

- Motor graders

- Dozers

- Crawler loaders

- Excavators

- Backhoes

- Wheel loaders

- Skid steers and compact track loaders

“We focus on putting technology to work for our customers. We bucket the technology based on two important outcomes—uptime and productivity,” said Leconte.

Addressing customer needs for operator training

Leconte said operator training has become a hot topic in the last few years. Ten years ago John Deere started hearing concerns from its customers about skilled labourers, and lack thereof.

“With these concerns, we wanted to react. We conducted surveys and worked closely with our customers. We found that one of their biggest concerns going into the future was attracting, training, and retaining skilled operators. Operator training continues to be a concern to this day and is more important than ever.”

Operator training and retention has become a hot topic in the last few years. Photo: John Deere

It’s important to realize that operator training is changing as well and we need to be on top of it.

“If you asked people in our industry in the last five to 10years ago if it was possible to effectively train new operators in a risk-free environment without burning money on fuel and equipment damage, they might have thought you were a little crazy. But today that type of training is available through new technology and tools that we offer,” said Leconte.

Operator training solutions equipment

John Deere offers several options to keep up with changing trends in operating training technology. The company has training DVDs, videos you can watch on YouTube, the option to enrol in John Deere University, and also uses simulators to train operators.

“John Deere University offers the same courses and content as our DVDs, but they’re offered in a training environment where you’ll have quizzes, tests, things like that, where you can track students’ activity,” he said.

John Deere developed its first simulator more than 10 years ago.

“It was an excavator simulator, back in 2008. We’ve added new features and new machines over the years. In 2018 or 2019 we started to see the need for a modular simulator,” said Leconte. He explained that a modular simulator allows for the ability to swap out controls and train on different machines from one simulator without having to make the investment or space needed for an individual simulator for each machine.

John Deere started looking for someone to help create this type of simulator, which led them to CM Labs.

“We felt CM Labs had one of the best modular designs out there. We really felt that the swappable controls were easy to do. They functioned very well. And they didn’t have all the cords associated with swapping things out sometimes. The graphics were unreal, very realistic—we love the look of them,” said Leconte.

Cm Labs also has the ability to integrate the machine and physics into the simulator so that it looks and functions exactly as the real John Deere equipment does.

“We didn’t want to put a generic machine out there that wasn’t going to feel like our John Deere equipment. With the use of their [CM Labs] physics engine and software we’re able to replicate that machine as closely as possible,” said Leconte.

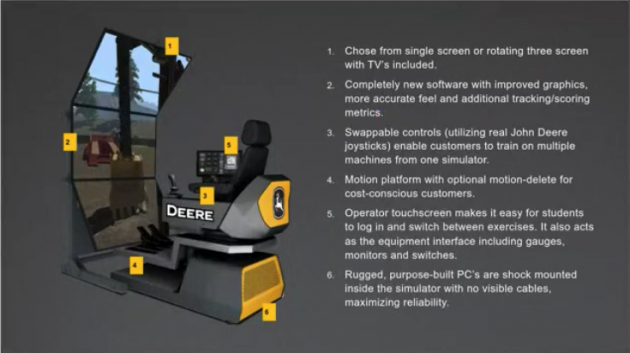

Some of the features offered on the John Deere modular simulator. Photo: John Deere

Leconte said the addition of swappable controls on the simulator is a big highlight and is an excellent solution.

“This will enable the customer to train on multiple machines from one simulator. You can quite literally change the simulator from an excavator to say a crawler or a grader in a matter of minutes.”

Print this page