Features

Education

Event Reports

OHMPA 2009 Fall Seminar: 5 steps ‘On the road to better pavements’

The 2009 Ontario Hot Mix Producers Association (OHMPA) seminar

February 25, 2010 By Andy Bateman

Building on his 2006 Fall Asphalt Seminar presentation, keynote speaker

Dale Decker explained that the demand for highways, change in the

industry, health and safety, funding, the environment, and quality

remain central issues for the hot mix asphalt industry.

Building on his 2006 Fall Asphalt Seminar presentation, keynote speaker Dale Decker explained that the demand for highways, change in the industry, health and safety, funding, the environment, and quality remain central issues for the hot mix asphalt industry. The five steps to better pavements target all of these issues with a pavement design that addresses quality and function, specifications that clearly define work, inspection to ensure proper construction, construction combining technology and craftsmanship, as well as effective maintenance and rehabilitation to preserve the investment.

|

|

| Attendees at the 2009 Ontario Hot Mix Producers Association (OHMPA) gained insight on the five steps to better pavements.

|

The evaluation of the existing pavement is an essential step in pavement design and includes a distress survey, assessment of the existing pavement structure and soil conditions. Pavement catalogues can help with elementary and repetitious designs but do not address opportunities for mechanistic empirical analysis, new materials or new mix designs. Additional project evaluation parameters include structural evaluation, traffic data, plus knowledge of subgrade and environmental conditions.

Specifications describe the design in a manner that can be constructed, processes, materials and equipment and should eliminate ambiguity and vagueness. Before work starts, specifications should be carefully reviewed to ensure they are fair, reasonable and enforceable. Specifications should also accurately represent the design and be current with state-of-the-practice. Old specifications should be kept in the past.

Decker reviewed Method Specification, End-Result Specification and Performance Specification, commenting on the advantages and disadvantages of each method.

In Decker’s view, performance testing is crucial to future development in industry as it allows the evaluation of new materials and can offer innovation opportunities for contractors.

|

|

| Miller Paving demonstrates proper subgrade preparation.

|

The purpose of inspections is to ensure that owners get what they want and agencies have fiscal responsibilities to ensure that they are getting what we paid for, that inspectors are properly trained and that an appropriate quality management plan is in place. Essential elements of the plan include certification of technicians and laboratory accreditation.

Dekker described construction as a three legged stool of quality, safety and productivity. The contractors’ mission is to understand plans and specifications and build a quality product. Ideally, the relationship between owner and contractor is one of a partnership to value. Responsibility is shifting from the agency to the contractor with contractors’ responsibilities now ranging from mix design to quality assurance. An effective quality management system assures that the final product meets job specifications as well as satisfying the customer’s needs as economically as possible. Opportunities for value engineering arise when the owner is open to the contractor’s ideas and the contractor should share in the value received by owner. Customer focused construction aims to provide road smoothness and durability with minimal delay. For the travelling public, smoothness is issue number one, while minimal construction delays are achieved by adopting the maxim of get in, stay in, get out, stay out.

Maintenance and rehabilitation are not perceived as “sexy”, unlike high profile new construction, which is typically popular with politicians. Nonetheless, rehabilitation is cost effective as $1 spent today can save $7 in rehabilitation costs in a decade. Unfortunately short term needs often overrule long-term priorities. As a result, road maintenance often consists of overwhelming requirements with little or no financial support. Asset management can be a useful strategic approach to help fight shrinking resources, both human and financial, and maximize the benefits from resources used to operate, expand, and preserve the transportation infrastructure.

Designing pavements to last

Chris Raymond of the Ministry of Transportation Ontario (MTO) reviewed aspects of pavement structural design, hot mix asphalt design and other considerations in “Designing pavements to last.” Input considerations to structural design include traffic, subgrade soil, drainage, the environment, material properties, pavement performance, multiple design, alternatives, life cycle costs and reliability. Raymond described the structural design tools available to engineers, adding that pavements should be built on a good foundation that, ideally, avoid utilities and frost susceptible soils while incorporating appropriate subgrade and granular subbase and base materials. Pavements wear from the top but fall apart from the bottom, and the proper evaluation of the existing pavement is essential to selecting appropriate designs.

|

|

| The “Step Test”: improper subgrade preparation is a common cause of asphalt overruns. |

Raymond’s review of hot mix asphalt design described Superpave mix design criteria and quality requirements for asphalt cement and aggregates , while other design considerations included available funds, operational considerations (maintaining traffic, user delay costs), the availability of materials/equipment, the marketplace (availability of contractors to take on more work), sustainable design and quality construction.

Thick asphalt lifts offer a number of advantages, including the optimization of the number of passes by compaction equipment, better compaction due to heat retention, reduced permeability/porosity, are less prone to segregation and mitigate reflection cracking. However, costs drive most agencies to place minimum thickness!

For improved pavement durability, contracts should be timed to avoid poor weather as late season paving can lead to problems such as rapid cooling of the mix, cold joints, poor bonds between lifts, thermal segregation and tack coat curing. Techniques to improve or avoid longitudinal joints include echelon/tandem paving, temporary ramping and integral shoulder/driving lanes. Raymond concluded that designing pavements to last requires good structural design, good materials and the facilitation of good construction.

Subgrade issues, asphalt overruns

In “Subgrade Issues, visual test procedures, ” Joe Bunting of the Miller Group utilized informative and amusing photographs of unofficial “visual test procedures” to demonstrate the importance of proper subgrade preparation. Bunting’s afternoon presentation utilised a similar approach to demonstrate causes and cures for asphalt overruns. Common causes of asphalt overruns include poor subgrade preparation, soft subgrade, incorrect structure elevations, paving on frozen grade, irregular base course and settlement. Additional causes identified were not properly matching curb or structures, incorrect density calculations in square metres, having the paver screed incorrectly set with a crown, poor design and layout, poor workmanship and improper communications. Bunting’s cure list was much shorter: the cure is teamwork.

Troubleshooting mat quality issues

Fernando Magisano of K.J. Beamish Construction Co., Ltd presented “Troubleshooting mat quality issues,” and began by questioning why paving problems are often blamed on the finished mat. The reason is that the last thing done, the mat, is the place where defects such as cracking, rutting, depressions and shoving are first observed. However, quality issues in the field are rarely superficial and the key issues that most contractors can control originate with issues related to mix properties, compaction, segregation and smoothness. So, how do contractors avoid these issues?

|

|

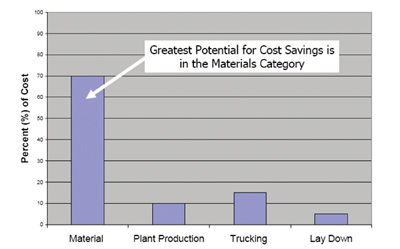

| Increasing RAP usage is the greatest single upfront cost saving measure available. Source: OHMPA.

|

Variations in mix properties can be due to moisture, aggregate or plant issues, and cause shoving, checking, flushing and compaction issues. Practical measures to deal with moisture related issues includes daily QC moisture checks (aggregates and mix), a check on load-out techniques, slowing down the hot mix plant, reducing RAP usage. A small amount of silicone can help.

Measures to avoid aggregate related issues include daily QC gradations (incoming and load-out), checking for variability in bulk densities and also checking that the right materials are being used.

To avoid plant related issues, complete plant trials for new mixes, take daily QC hot mix samples and complete full mix testing. Other measures include a check of the fines return systems, a re-check of cold feed calibrations and, avoid starts and stops whenever possible.

On site, variability in compaction can be caused by changes to mix properties or mix temperature due to plant variations or roller variability. To avoid plant variability, minimize stop and starts in operations, check material gradations and use the Bailey method to check for potential problems (packing characteristics).

To avoid roller variability, use portable gauges to set-up roller patterns, use soap solutions, heaters, hot sand pads or high speed warm-up passes as appropriate to help pneumatic rollers get onto the hot mat more quickly. Use infrared thermometers to stay “in the zone.”

Segregation and smoothness issues can originate in a number of places; during mix production, haulage and at the paver, while project constraints and challenges may also play a role.

Production and haulage issues can usually be prevented by a check on stockpiling and load-out techniques, using fractionated coarse aggregates and fractionating processed RAP, checking truck loading techniques, using heavy tarps to cover the load on haulage trucks. On site, the use of a Material Transfer Vehicles (MTVs) will remix the asphalt, avoid paver bumping by delivery trucks and lay-down stoppages. Good paver practices need to be maintained such as the use a dump person to avoid spills in front of the paver and avoiding the emptying of the paver’s front hopper, slat conveyors or auger chambers. In addition, paver and tail-end operators should understand all feeder, screed controls and grade adjustments and make full use the paver’s automatic depth and slope controls whenever possible.

Project constraints and challenges that can impact segregation and smoothness include the challenge of maintaining minimum depths for quality and still maintain average depths for proper mix distribution. If possible, avoid variable depth paving situations by allowing for padding and / or profile grinding. Other challenges can include matching into existing curbs, catch basins, mechanical devices, adjacent lanes, crossroads, and other site characteristics. In addition, single lift paving can be a challenge on scabbed ground surfaces and also on Cold in-place recycle (CIR) and Cold in-place expanded asphalt mixture (CIREAM) surfaces.

Magisano concluded with a comment on the familiar challenges of poor weather and traffic allowances; where possible, adjust paving schedules to avoid cold weather and consider temporary road closures to separate live traffic from construction zones. Closures allow the contractor to place more tonnage in a shorter time period and possibly avoiding the late season challenges.

Editor’s note: additional information and presentations from the OHMPA seminar are available at www.ohmpa.org.

Print this page