Products & Equipment

Pits & Quarries

Conveyor Systems Update

Taking a look at the newest technology for conveyor systems in Canada.

February 12, 2014 By Rock to Road

In this issue of Rock to Road magazine, we take a look at the newest

innovations from conveyor systems manufacturers that service Canada’s

aggregates and roadbuilding industry.

In this issue of Rock to Road magazine, we take a look at the newest innovations from conveyor systems manufacturers that service Canada’s aggregates and roadbuilding industry.

Screen Machine

The Screen Machine Industries model 6036T track-mounted portable stacking conveyor sets the standard in the conveyor industry. This wireless remote controlled conveyor will match up perfectly to any track-mounted crusher or screening plant and offers fingertip mobility. A counterweighted design combines with a heavy-duty channel frame structure to create unequalled stockpiling capability. Hydraulic top folding head section and cylinder positioning makes transportation and set-up quick and simple.

|

GreyStone

GreyStone, Inc. offers a full line of conveyor systems, with lengths ranging from 50 to 200 feet, custom-designed to meet specific application needs. All conveyor systems have standard CEMA idlers and a lagged-head pulley design with a rubber-coated gripping surface that ensures a tighter hold on conveyor belts to minimize slippage as well as a self-cleaning, wing-type tail pulley eliminates debris build-up and reduces belt damage.

|

Superior

Superior Industries Inc. says it manufactures the highest-capacity telescoping radial stacker on the planet. Measuring 72 inches wide by 190 feet long, the high-capacity TeleStacker® Conveyor can stockpile aggregates and other bulk material at rates up to 5,000 tons per hour. Since building its first telescopic radial stacker in 1997, Superior has since designed and built 1,000 more units.

|

KPI-JCI

KPI-JCI and Astec Mobile Screens has released a new 170-foot-long SuperStacker™, its latest model of telescoping stackers designed to minimize stockpile segregation and increase stockpile capacity. The 170-foot SuperStacker™ is an addition to the new generation of SuperStackers that eliminates the echain, thereby reducing field maintenance. The new model also features an updated Wizard Touch® automation control system, which allows for more stockpiling options and a higher-quality product.

|

McCloskey

The TF80 tracked feeder from McCloskey International has new features to enhance and streamline the stockpiling of materials.

Full remote control on all functions is now available, saving time and money by allowing operators to track and run the machine without getting out of the loader.

In response to customer feedback, the TF80 also has a new lower operating angle to allow it to convey a wider variety of material without blockages, bottlenecking or bridging.

Assinck

Assinck Limited has been supplying conveyor components and processing equipment to the aggregate industry since 1952. Assinck Limited operates from Scarborough with a manufacturing area over 60,000 square feet.

Assinck Limited custom designs and manufactures portable and stationary conveyors, ready-mix plants, and crushing, screening and washing equipment to suit your requirements. Every aspect of the design and manufacture of Assinck Limited products and equipment is directed toward quality, performance and customer satisfaction.

|

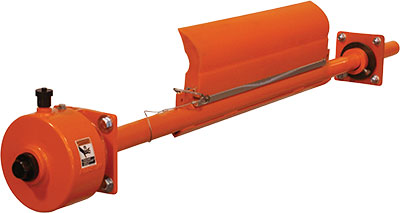

Martin Engineering

A global leader in bulk material handling technology has announced a conveyor belt cleaner engineered specifically for the aggregate industry. The Martin® PV™ Cleaner is a durable, one-piece blade that contains approximately 20 per cent more urethane than comparable primary cleaners, yielding a longer life in challenging service conditions. This aggressive design for gravel applications is able to remove even wet, sticky sand from belts 18-72 inches (450-1800 millimetres) wide.

|

Rosta

Rosta, a leading manufacturer of dynamic rubber suspension elements whose unique design has multi-functional uses, offers self-tensioning motor bases that are used on a wide range of V-belt driven equipment. With sizes ranging from fractional to 500 horsepower, they are able to extend your belt and sheave life and provide a positive drive without slippage.

|

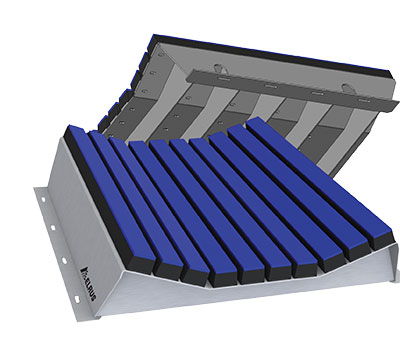

Elrus

Elrus Impact Beds are designed to protect conveyor belts at key transfer points, provide load support and reduce spillage. One piece formed heavy-duty carriage construction provides increased support to withstand impact forces. Replaceable impact bars are constructed from a high-impact rubber bottom and low-friction UHMW polyethelyne top and are secured with ½-inch t-bolts.

For more information on conveyors, be sure to check out the New Products section of www.rocktoroad.com for the newest releases from these and other manufacturers of conveyor systems and components.

Print this page