Products & Equipment

Pits & Quarries

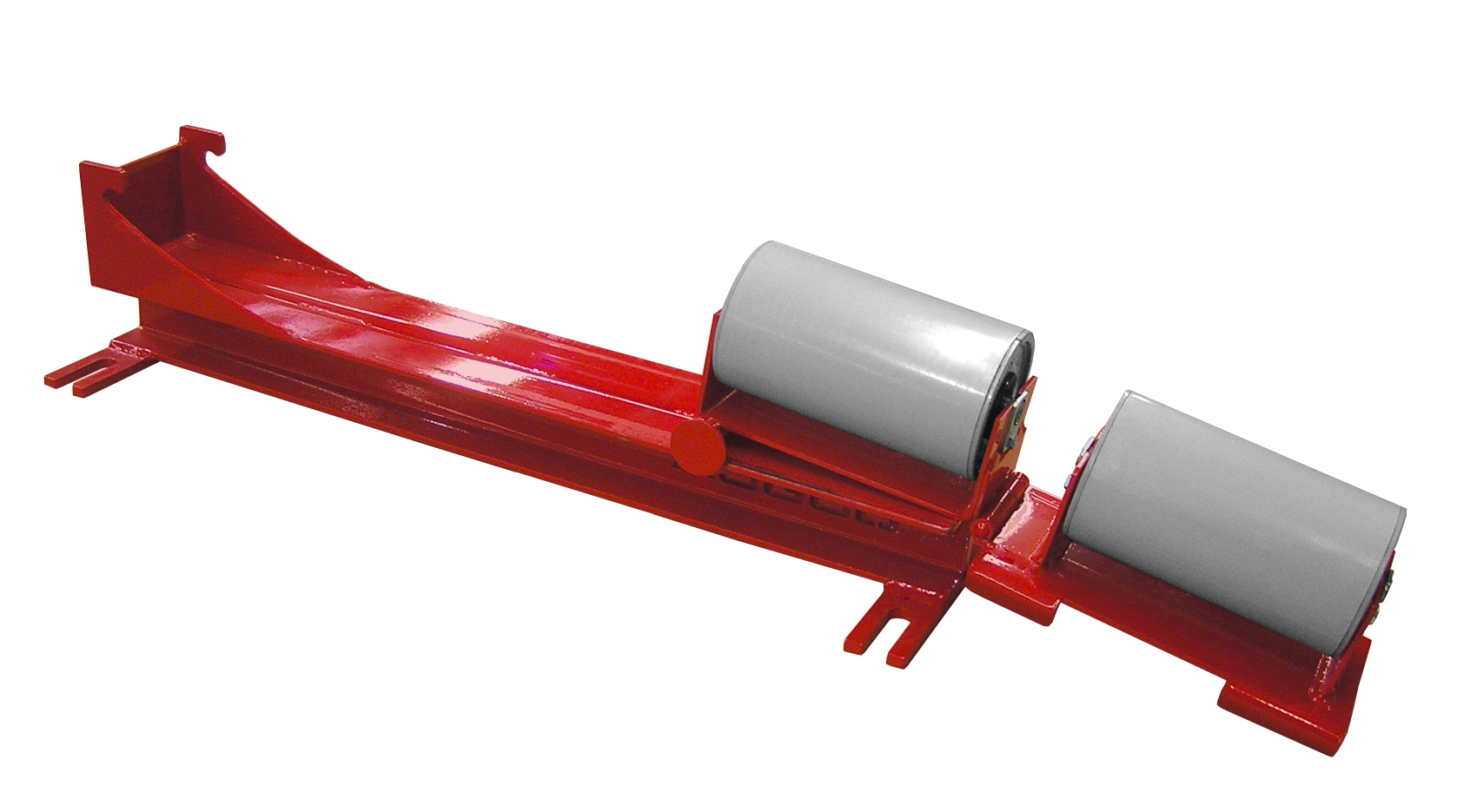

ASGCO releases the one-sided Slide-ler

December 10, 2015 By Andrew Macklin

December 10, 2015 – ASGCO’s new patent pending One-Sided Slide-lers give you the ability to change idler rolls under the conveyor loading skirt area without having to remove adjacent belt idlers. This allows the One-Sided Slide-ler to fit into tight or confined spaces, ensuring proper belt rolling support and ease of change out.

The new ASGCO One-Sided Slide-ler is a modular designed product that allows you to remove the wing and center roll hangers for easy replacement of your idler rolls. It can also be designed to hold any manufacturer roll in the industry. The One-Sided Slide-ler minimizes down time and can be accessed from either side of the conveyor system.

For environments with extreme access limitations, ASGCO’s new One-Sided Slide-ler’s product is designed to be maintained from just one side of the conveyor system. This is ideal for systems with access on one side only, where a conveyor is located against the wall or high in the air with catwalk on one side. This allows you to replace rolls with minimal downtime and eliminate the need for man lifts or having to work in a confined space. The product is ideal for aggregate and mineral mining applications.

Key Features

• Frames only take up 8″ (200mm) of width when using 6″ (150mm) rollers

• Allows for easy replacement of rollers in any environment

• Compatible with all manufacturer rollers

• One-Sided model for limited access applications

• Available for any belt width, troughing angle or idler

Benefits

• Perfect for confined spaces

• Improves safety

• Meets all CEMA Standards

• Total Satisfaction Guarantee (TSG) – ASGCO’s customer service policy ensures your satisfaction.

Print this page