Features

Aggregates

Profiles

Dufferin Construction builds Canada’s Infrastructure

Dufferin Construction Company as the Roadbuilder of the Year for 2008

January 2, 2009 By Aggregates & Roadbuilding Staff

Aggregates & Roadbuilding proudly announces Dufferin Construction Company as the Roadbuilder of the Year for 2008.

|

|

| DCC utilised Rapid Bridge Replacement technology to successfully replace the Queensway bridges over Island Park Drive and Clyde Avenue in Ottawa during the 2007 and 2008 construction seasons respectively.

|

Almost a century old, the name Dufferin Construction Company (DCC) is synonymous with major construction projects in Canada. The company, together with its operating units, TCG Asphalt and Construction and Cayuga Asphalt and Construction, is one of the largest heavy civil engineering contractors in the industry. DCC is a business unit of St. Lawrence Cement Inc. (a member of the Holcim Group), a leading producer and supplier of products and services to the construction industry in Canada.

Founded in 1912 by a young Italian Immigrant, James F. Franceschini, the company grew into what it is today by its sheer determination, hard work and sound business principles. The ability to offer fully integrated construction services combined with a wealth of experience and the versatility to bring innovations and efficiencies to any project is not something many companies can replicate.

Approaching 100 years of history, DCC has contributed to many major projects across Canada. From its first major highway project on the Dundas Highway in 1921, participating in the construction of the Alaskan highway in the 1940’s, to more recent construction of airports and highways across the country.

Underpinning the company’s growth and development has been the implementation of a robust health and safety management system. The company’s safety performance has been recognized, including the Canadian Construction Association’s National Safety Award in 2001 and 2006. Following are some key projects that have the DCC signature.

|

|

| Part of Dufferin Concrete’s ready mix concrete truck fleet in action at Toronto’s Lester B. Pearson International Airport. |

Pearson International Airport – Toronto, Ontario:

Over the past 10 years, the Lester B. Pearson International Airport has been in a constant state of construction. The new Terminal 1 allowed for the demolition of the existing Terminals 1 and 2 requiring the construction of a new concrete apron area and the complete re-development of the roadway system leading into the airport. DCC was a key player in all phases of the decade long project that transformed Toronto’s airport into a world class facility. Construction services provided by DCC on multiple projects exceeded half a billion dollars.

Hwy 410 Extension – Brampton, Ontario:

A $50.2 million dollar contract with the Ontario Ministry of Transportation, the 5.4 km northward extension of Highway 410 from Bovaird Drive to Mayfield Road located in Brampton, Ontario is almost near completion.

The Highway 410 extension project includes the construction of a six lane divided highway and two pre-stressed concrete girder bridges over Hwy 410. The work involved upward of one million cubic meters of earth excavation and grading and 7.3 km of storm drainage sewers.

This project was tendered by the Ministry of Transportation as an alternative bid, with the Portland cement concrete pavement winning over the asphalt pavement option. Concrete paving was a key component of this project and DCC has an unmatched reputation in this field.

|

|

| Track work for the Toronto Transit Commission.

|

Bridge Replacement Projects Using Rapid Lift Technology:

The first Rapid Bridge Replacement in Canada was implemented by DCC. Using the Rapid Bridge Replacement technology, what usually takes a couple of construction seasons to complete DCC delivered in a matter of hours. This Canadian first was featured in a documentary by the Discovery Channel.

DCC has successfully replaced the Queensway bridges that pass over Island Park Drive and Clyde Avenue in Ottawa during the 2007 and 2008 construction seasons respectively. The Queensway (Hwy417) is the main thoroughfare for the Ottawa area carrying over 150,000 vehicles per day with three to four lanes in both directions.

Rapid Lift Technology allowed for the rehabilitation of the existing bridge abutments concurrently with the construction of the new bridge decks in an adjacent staging yard. Utilizing traditional methods, each project would have taken two full construction seasons to complete that would include hundreds of daily lane closures or restrictions to facilitate staging. The Ministry’s decision to close the Queensway for one 15 hour shift on each project to facilitate the replacement allowed the entire project to be completed in two years vs. the four required by traditional method.

Reduction of traffic congestion due to the new technology has two major benefits. Firstly, there will be decreased wear and tear on vehicles, better fuel consumption, and a decrease in pollution and greenhouse gases that contribute to climate change brought on by idle slow moving vehicles. Secondly, a reduction in traffic congestion has positive impacts on the economy. Market research firms continue to provide estimates on the negative financial impact that highway congestion has on business.

The Ontario Ministry of Transportation took a leadership role in bringing the new technology to Canada for use in highway construction for the first time. McCormick Rankin Corporation performed the detailed engineering design work on behalf of the Ministry while Mammoet Canada Eastern Ltd. was subcontracted by DCC to perform the specialized heavy lift component.

Edmonton Airport Apron Expansion – Edmonton, Alberta

Edmonton International Airport (EIA) in Alberta is undergoing a major, three phase expansion. The Edmonton Regional Airport Authority is predicting that the EIA will surpass 9 million annual passengers by the year 2012, requiring the expansion of passenger and aircraft facilities. The airside concrete apron is being doubled in size to accommodate more aircraft.

In 2007, DCC completed a 65,000 m2 concrete apron expansion project. In 2008, Dufferin was awarded a second contract in excess of $60 million to expand the concrete apron by another 320,000 m2. The scope of work in addition to the concrete paving includes installation of storm sewers, earthworks, granular placement and electrical improvements.

|

|

| Echelon hot mix asphalt paving at night on the Queen Elizabeth Way (QEW).

|

Queen Elizabeth Way (QEW):

The QEW is a major trade corridor linking Toronto to the Niagara region and is the principal route to four international crossings over the Niagara River to New York State.

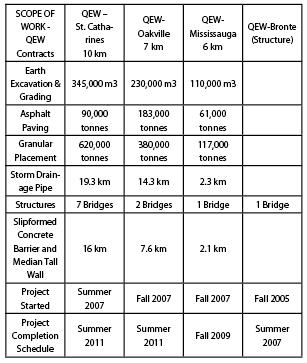

DCC is currently leading four construction projects on the QEW from Toronto to St. Catharines with a combined value in excess of $300 million. The QEW project in St. Catharines valued at $153 million was the largest contract ever awarded by the Ontario Ministry of Transportation.

These projects will span four construction seasons.

Kenilworth Access – Hamilton, Ontario

DCC was awarded the $6.2 million dollar contract by the City of Hamilton in the summer of 2008 for the reconstruction of Kenilworth Access. Kenilworth Access is a mountain-access road at the base of the Niagara escarpment in Hamilton, Ontario. It is an important link for residents wanting to access the industrial North end of the City. In addition to reconstruction of drainage system, pavement structure, and other surface works, the City of Hamilton paid special attention to the aesthetics of the project given its location on an environmentally sensitive and highly visible escarpment.

This challenging project was completed in record time according to a demanding schedule required by the City.

A recent DCC innovation, the Dufferin SlipStone Extruded Wall System, was instrumental in producing the aesthetic improvements required by the job. The technology, recognized by the Canadian Construction Association for Excellence in Innovation, was designed to provide a wide range of applications ranging from highway traffic barriers and gateways, to retaining walls, subdivision perimeter walls and architectural facings.

Be it a major infrastructure project such as highways, bridges and concrete or asphalt paving or commercial, industrial and residential developments, DCC has been a integral part in contributing to building and shaping the Canadian infrastructure that we see today. n

|

www.dufferinconstruction.com

www.dufferin-slipstone.com.

Dufferin Construction

Company (DCC) is a business unit of St Lawrence Cement, a leading producer and supplier of products and services for the construction industry in Canada and a member of the Holcim Group. Holcim is one of the world’s leading suppliers of cement and aggregates as well as further activities such as ready mix concrete and asphalt including services. The Group holds majority and minority interests in more than seventy countries on all continents.

Print this page