Products & Equipment

Roads & Bridges

ACE intelligent control for compact applications

August 18, 2010 By Aggregates & Roadbuilding

NEW PRODUCT

NEW PRODUCT

ACE intelligent control for compact applications

Ammann now offers the same ACE

technology on its AVH 6030 model, a three-shaft high performance

vibratory plate compactor, as it does on its heavy equipment line.

Aug. 18, 2010, Mississauga, Ont. – Ammann now offers the same ACE technology on its AVH 6030 model, a three-shaft high performance vibratory plate compactor, as it does on its heavy equipment line.

With the introduction ACE on this model, Ammann Canada now offers intelligent compaction control across a range of soil and asphalt compaction applications.

|

|

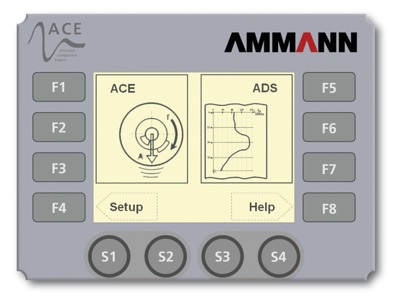

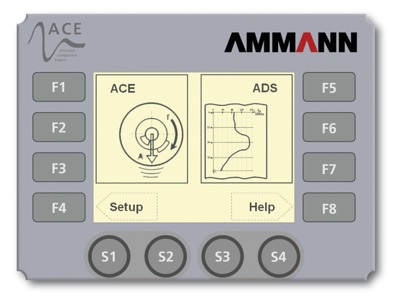

| The ACE system is simple to operate using the selector switch.

|

ACE, the Ammann Compaction Expert, is an electronic measuring and control system for vibrating rollers that automatically adjusts the amplitude and frequency to suit the characteristics of the ground. The system has been available in larger Ammann machines for several years, helping operators to achieve target levels of compaction without over-compacting or loosening material.

Peter Price, the Ammann Area Sales Manager in Canada, says that “these ACE systems supply operators with a constant flow of compaction results that lets their work progress as efficiently as possible to get the best compaction results.”

Real-time information for faster, accurate results

ACE-equipped machines provide continuous measurement of absolute compaction values, automatic adjustment of compaction parameters and comprehensive documentation of the compaction process.

|

|

| The operator is supported constantly by a clear and simple display.

|

Providing the operator with real-time information and response improves profitability on the job site by reducing the number of passes to achieve compaction targets; reducing the time and cost to complete the project and by eliminating over-compaction or demolition of the material.

ACE manages the machine’s compaction effort according to its reading of the layer’s load bearing capacity. The system automatically reduces the compactor amplitude in hard areas, and increases amplitude where load capacity is low. The operator is presented with a clear and simple display of machine and compaction data; including continuous readings for current amplitude and frequency. The display also provides the recommended speed for optimum compaction, so the operation can be completed accurately in the fewest possible passes.

Consistent results for soil or asphalt compaction

In addition to completing jobs more efficiently, compactors equipped with ACE can show their operators where soft spots or un-compacted areas are located in the material so they can improve the quality of the layer. As a result, ACE leads to a more homogenous compaction throughout the material, and ensures the uniform load-bearing capacity through all layers to provide an ideal base for asphalt.

For tandem rollers, ACE also ensures consistent compaction levels and bearing capacity and achieves an optimal surface structure. ACE is able to monitor the temperature of the asphalt and will prevent the machine from compacting if the mat is too hot or too cold. ACE also allows early identification of trouble spots beneath the surface, where the subsoil is not up to the required load bearing capacity.

CCC documentation

On the larger machines, the ACE system records all data on the bearing capacity of each soil or asphalt layer to meet requirements for CCC (Continuous Compaction Control) documentation. Captured data can be exported via standard USB storage devices. This record of continuous readings enables contractors to identify non-compactable areas and take any necessary remediation steps, such as soil stabilization or material exchange.

Advanced mapping and communications

Ammann recently introduced updated versions of its compaction control with the ACEplus system including new GPS technology. This system, available on the larger machine puts onsite mapping of compaction results into the operator’s compartment through a touchscreen PC display. The graphic display represents a range of quality values including load-bearing capacity, number of passes, temperature and other details. The GPS signal in ACEplus can also be used to upload CCC data to remote IT systems for analysis and archiving.

For further information on Ammann products and service in Canada, contact:

Peter Price, Area Sales Manager – Canada

Ammann Canada

Mississauga, Ontario

289-997-3758

peter.price@ammann-group.com

Print this page