Products & Equipment

Pits & Quarries

Equipment Spotlight: Dewatering Systems

The newest system for dewatering and sand removal

August 13, 2015 By Rock to Road Staff

McLanahan

McLanahan

McLanahan Ultra Sand Plants increase sand production, produce drier product and improve product consistency. Combining a Separator, dewatering screen and slurry pump, Ultra Sand Plants provide a three-to-five per cent higher product yield over traditional fine material screw washers. They operate efficiently, keeping product sized fines and sending unwanted fines to waste streams. They also have the ability to separate and combine sand fractions, allowing producers to blend sands as needed to meet product specifications.

KPI-JCI

KPI-JCI

KPI-JCI and Astec Mobile Screens’ new S9000 Dewatering Screen is capable of reducing moisture content of washed sand down to as low as eight to 15 per cent. It is available in multiple sizes, ranging from 2’ x 7’ up to 8’ x 16’. The screen’s ¼”-stroke operates at 1200 RPM, providing high “G” force action to separate water from the material. It is equipped with urethane media, has an adjustable incline from 0 to five degrees, and can be packaged in portable, semi-portable and stationary systems.

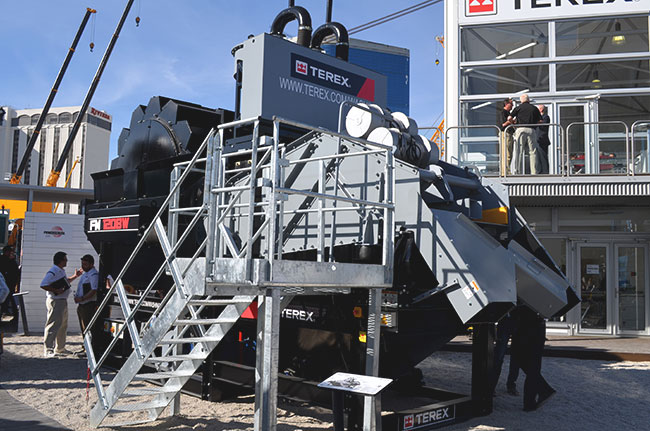

Terex Washing Systems

Terex Washing Systems

Terex AggreSand system combines aggregate washing and screening with sand processing on a modular chassis. It brings together Terex Washing Systems quality components in an innovative modular design. Central to the development of the new plant is a modular design, pre-wired and pre-plumbed making it quick and easy to set-up and easy to maintain. The plant also includes a range of other innovative features and designs.

Fisher Industries

Fisher Industries

Fisher Industries is able to custom design and mount washing plants with most major brands of washing equipment and in combination with: single and multiple deck screens, single and twin paddle log washers, single and twin shaft sand screws, course material washers, sand pumps, water manifold and spray bars, and slurry feed boxes. A Fisher Industries Wash Plant can be designed as either a stationary or portable plant.

Haver & Boecker

Haver & Boecker

The Hydro-Clean washing unit from Haver & Boecker effectively cleans deleterious material from aggregate, recycled and other minerals while reducing water consumption by as much as 75 per cent compared to traditional log washers. Taking feed material as large as six inches, or 150 millimeters, into its vertical drum, the Hydro-Clean employs high-pressure nozzles, rotating at 90 rpm, to spray as much as 90 per cent recycled water on the material with pressures as high as 2,000 psi (140 bars).

CDE Global

CDE Global

The M2500 is the world’s first fully integrated mobile washing plant and offers feeding, screening, sand washing and stockpiling on a compact, portable chassis. The M2500 has many installations on a wide range of materials including sand and gravel, crushed rock, construction and demolition waste recycling and scalpings.

Superior

Superior

The Superior Aggre-Dry Washer is a combination of a fine material washer and dewatering screen in a single machine. The processed material has eight per cent moisture, which requires no dry time and is instantly saleable. The patented fines recovery system returns fines to screw saving three per cent of material from waste pond. The dry material is gentler on loader tires and doesn’t stick to conveyor components.

Derrick

Derrick

The Derrick HI-G Dryer provides the most cost-effective solution to handling fines. This proven technology consists of a Derrick high G-force linear motion vibratory screen and a radial design cluster of Derrick 4″ uni-body hydrocyclones. The HI-G drastically reduces maintenance costs involved with cleaning settling ponds. All recovered solids are provided in a consistently stackable and conveyable form at 75 to 80 per cent solids.

Deister

Deister

The Deister UFR system is capable of recoveries to 350-400 mesh at feed capacities from 1500-3500 GPM. It utilizes a radial distribution manifold for even distribution of solids to all cyclones. The cyclones are available with a variety of liner and body materials. Victaulic connections allow flexibility and ease of maintenance.

Weir Minerals

Weir Minerals

Enduron dewatering screens have been designed with an innovative curved, sieve-like feed section. This curved profile increases dewatering capacities over the standard 45 degree sloped back deck, using centrifugal force to aid in the dewatering process. The main deck of the screen slopes upwards at five degrees and is fitted with slotted apertures. The end result is a series of screens that are engineered to provide maximum water recovery, increased load capacity and the lowest total cost of ownership.

Print this page