Products & Equipment

Pits & Quarries

Deister introducing EMCO 360 Crusher Optimizer Feeder at CONEXPO-CON/AGG 2017

February 21, 2017 By Deister Machine Co.

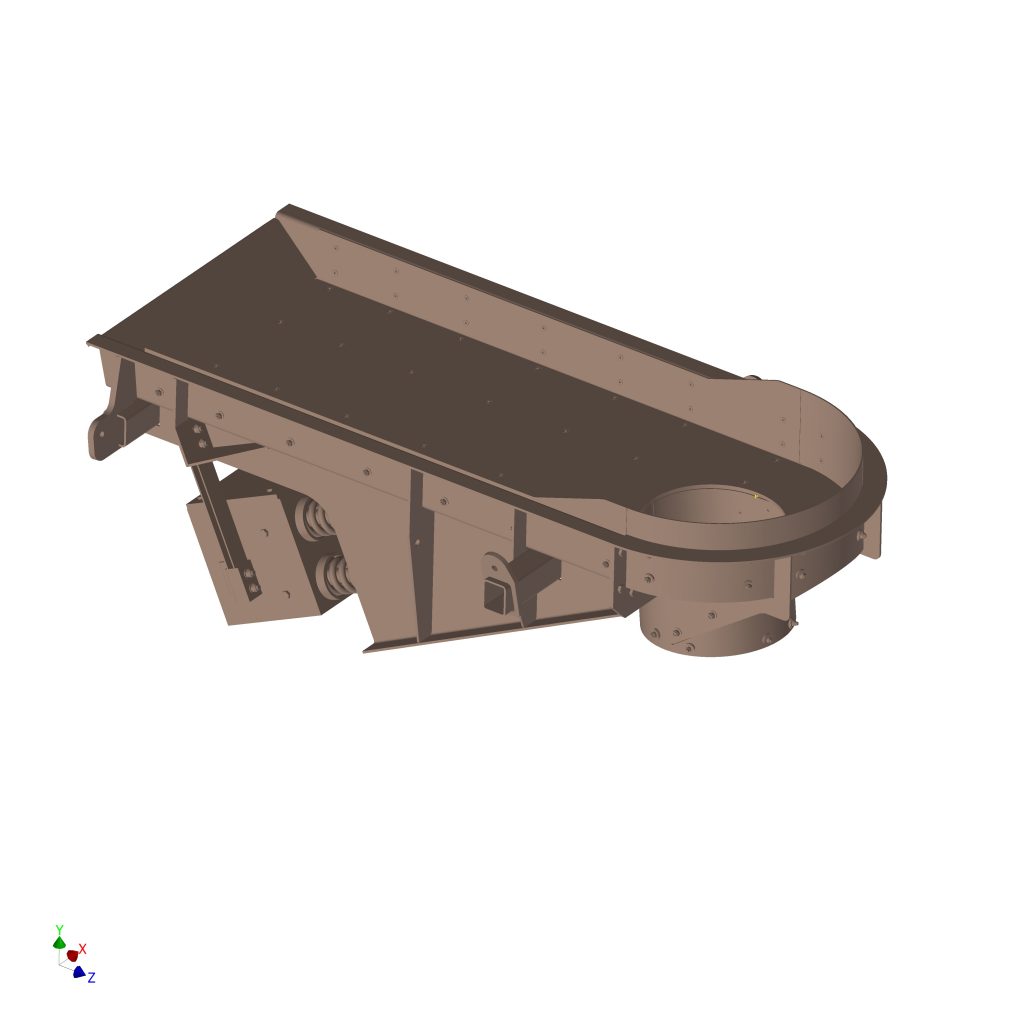

EMCO 360 Crusher Optimizer Feeder Image: Deister Machine Co.

EMCO 360 Crusher Optimizer Feeder Image: Deister Machine Co.February 21, 2017 – Deister Machine Co., Inc, introduces its new EMCO 360 Crusher Optimizer Feeder – the latest addition to its line of electromechanical vibrating feeders.

The EMCO 360 Crusher Optimizer Feeder is specifically engineered to optimize cone crusher performance. Featuring a 360-degree discharge opening, the unit distributes a homogeneous feed to cone crushers, keeping cones choke-fed for optimum efficiency, product consistency, and improved production rates. Available in a wide range of sizes and capacities, the Deister EMCO 360 Crusher Optimizer Feeder Series is backed with 24/7 parts and service support; stocked American-made parts; and a global network of dealers.

In addition to the new EMCO 360 feeder, Deister highlights several of its innovative screening, scalping, and feeding solutions at CONEXPO-CON/AGG 2017 in Booth# C31227:

Rugged and reliable triple-deck washing screen

Producers will view an operational Deister BHM-3824-03T, a 3-deck, 8-ft. x 24-ft. washing screen with a triple-shaft vibrating mechanism. Inclined screens with the mechanism located between the decks offer the most economical combination of capacity and mechanical simplicity.

The new (EMF-Series) Two-Mass Electromechanical Vibrating Feeder

The EMF Series is designed to allow greater control over high-capacity feed rates and productivity, while lowering costs per ton in a wide variety of aggregate, mining and mineral applications. Engineered to deliver greater reliability and ease of maintenance, the Deister EMF Series features a machine weight that is more robust. Units incorporate a high-profile infeed lip; and a heavy-duty formed deck with replaceable liners. A simplified drive is designed with an easy-access exciter frame, which houses the single vibrator motor. This results in higher bearing life, and eliminates the need to replace belts. Additionally, units feature energy-efficient pre-compressed steel transmission springs, which are not susceptible to temperature or shelf life; and heavy-duty spring isolation assemblies for suspension or support mounting. Deister offers expedited deliveries of one- to two-weeks on stock models.

Engineering expertise and quality assurance

Deister application engineers work closely with customers to develop customized solutions that meet the toughest specification challenges. Using state-of-the-art design tools, Deister engineers ensure that every screening and/or feeding component and circuit is designed to deliver greater efficiency while lowering operating costs per ton.

As a family-owned business celebrating more than century of manufacturing excellence, Deister Machine Company remains a customer-focused leader in the aggregate and mining industries. For more information on the new Deister EMCO 360 Crusher Optimizer Feeder; or on Deister’s complete line of feeding, scalping and screening equipment; visit www.deistermachine.com.

Print this page