Features

Education

Event Reports

World of Asphalt/AGG1

Previewing the newest technology that will be on display in Baltimore

February 10, 2015 By Staff Report

World of Asphalt/AGG1 is back in 2015, coming off the success of an incredible CONEXPO-CON/AGG in 2014 in Las Vegas

World of Asphalt/AGG1 is back in 2015, coming off the success of an incredible CONEXPO-CON/AGG in 2014 in Las Vegas and a strong show in San Antonio the year before.

CONEXPO-CON/AGG saw new technology push towards Tier 4 Final engine technology, operator comfort, portability, energy efficiency and hybrid machinery. Based on what major manufacturers from across North America and around the world have already discussed about the new technology coming to Baltimore this year, that trend will continue.

Here is a look at the new products, innovations and technologies that will be on display from major manufacturers in Canada’s aggregates and road construction industry.

|

|

Roadtec

Among the machines on display from Roadtec will be the RX-300e is a light and maneuverable milling machine with a base cutting width of 48” (1,200 mm) and the capability of cutting up to 12.5” (220 mm) deep.

The RX-300e is a 300 hp (224 kW) machine with a hydraulically driven cutter drum. The highly efficient hydraulic drum drive provides exceptional performance while reducing maintenance time.

A Cummins QSL 9, 300 horsepower (224 kW) Tier 4 Final compliant diesel engine powers the new mill. The RX-300e will replace the RX-400e model in the Roadtec line of milling machines.

|

|

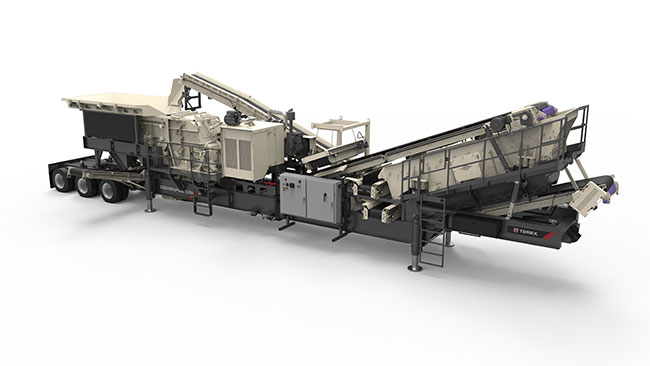

Terex MPS

The Terex Minerals Processing Systems (MPS) team is looking forward to meeting new and existing customers at AGG1 in Booth #1487. AGG1 is a great opportunity to dicuss new products and get personal time and feedback from customers and operators. Terex MPS has recently launched many new products, including the Terex® HSI4143 horizontal shaft impactor which will be on display. This new crusher features hydraulic apron adjustment, an optional blow bar jib crane, and an optional 3rd curtain grinding path.

|

|

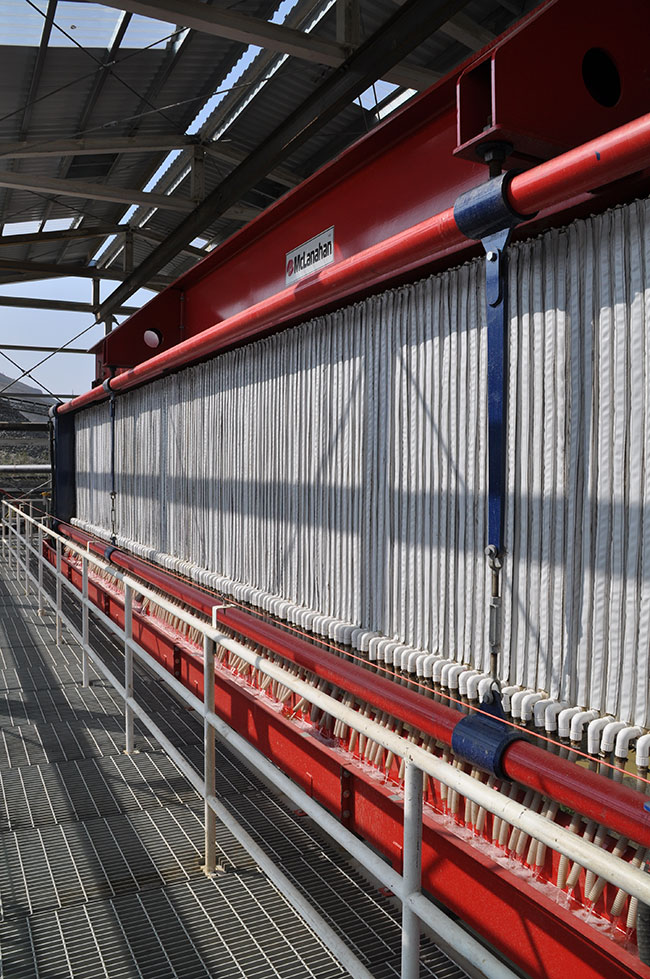

McLanahan

In Booth 1830 at AGG1, McLanahan Corporation will be showcasing its leading sand processing, fines recovery and water management systems, as well as its full line of safer, simpler and smarter processing solutions. Also featured will be the Freedom Jaw Crusher, the first real innovation in jaw crushers in over 100 years. The booth will include a working filter press and 3-D models of McLanahan’s complete equipment range for both wet and dry processing.

|

|

John Deere

The John Deere 824K-II Wheel Loader is equipped with a 333 hp (248 kW), Final Tier 4 emission certified engine that delivers power without sacrificing power or torque. The machine combines outstanding maneuverability, travel speed (24.9 mph), breakout force, reach, and stability. The 824K-II loader comes equipped with large, higher-capacity Teammate™ V Axles with standard cooling and filtration, and on-the-fly engageable front differential lock giving operators heavy-duty traction for the most demanding terrain.

|

|

Metso

Metso will highlight a range of new technologies at AGG1 this year, including the HP5 and GP7 cone crushers, C130 and C150 jaw crushers, rock breaker solutions, and the Lokotrack LT330D mobile crushing and screening plant. In addition, Metso will feature its new Orange Series Rotor for Barmac vertical shaft impact (VSI) crushers, and will display its advanced IC50/IC70 automation system, designed to improve a plant’s performance in terms of productivity, quality, safety and availability.

|

|

Hamm

Hamm’s new HD+ i-series line of Tier 4 interim-compliant tandem asphalt compactors include the 7-ton Hamm HD+ 70i VT, combining smooth drum with pneumatic tires; the 11.5-ton HD+ 110i VO Oscillation roller, combining standard vibration with exclusive Hamm Oscillation compaction; the 13.2-ton HD+ 120i VV HF, a high-frequency roller; and the 15.4-ton HD+ 140i VV, with standard vibration.

|

|

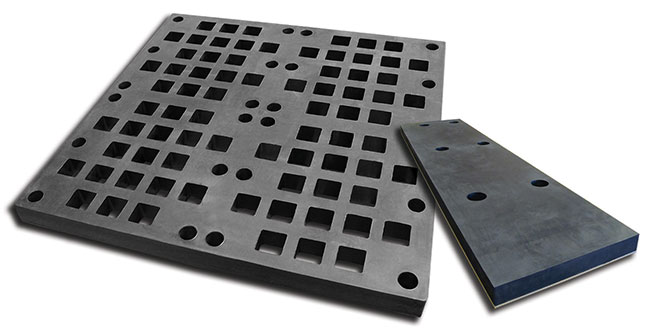

Polydeck

Polydeck Screen Corporation will have several examples of their industry-leading synthetic screen media on display at AGG1, including their Armadex line of top deck, high-performance bolt-down rubber screen sections and liners.

Armadex screen sections, available in sizes up to 48” by 96”, can be customized to match your frame dimensions and bolt-hole locations, and have proven to outlast competitive products by as much as 2 to 1. Polydeck will be in Booth 1734.

|

|

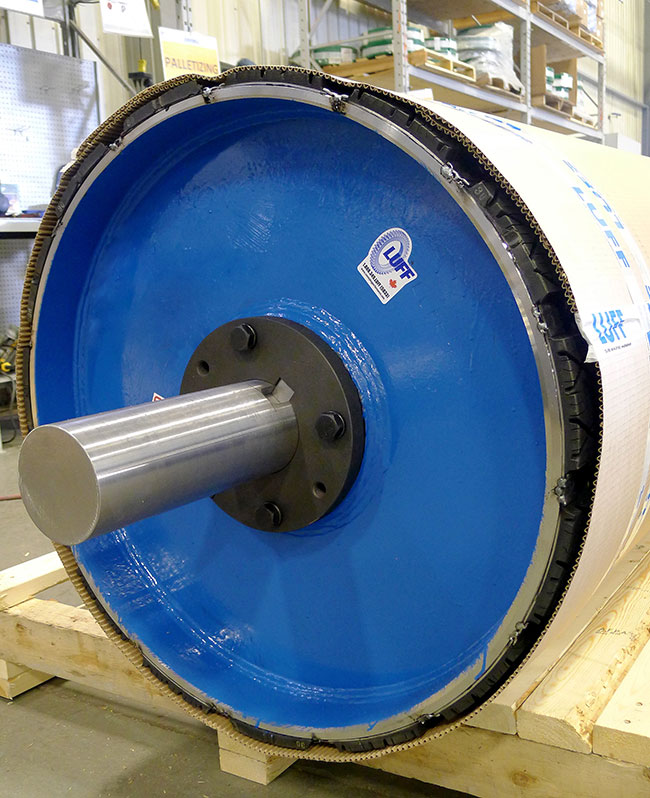

Luff Industries

Built to withstand the harshest of applications, Luff pulleys are unmatched in quality and dependability. Available in drum, wing, spiral and helical designs, Luff can custom design and engineer pulleys to meet your specific needs. Fabricated out of heavy schedule pipe, Luff drum pulleys are typically 50% thicker than the competition, which absorbs more stress, reduces shell deflection and protects against abrasive wear. Come check out a Luff Pulley at the World Of Asphalt/AGG1 Show in Booth #1607 to find out how it can improve your Conveying Performance.

|

|

Caterpillar

Caterpillar will be showing the new AP1055F paver at World of Asphalt. Several features help improve fuel economy while maintaining high performance levels. Engine performance is aided by the 167 kw (225 hp) Cat C7.1 ACERT engine, which meets U.S. EPA Tier 4 Final emissions regulations without sacrificing power.

Eco-mode is standard on F-Series pavers. When used with automatic engine speed control, Eco-mode efficiently manages engine RPMs to optimize fuel economy, reduce sound levels and keep the paver running smoothly.

|

|

Kleemann

New impact crushers from Kleemann – the Tier 4 final-compliant Mobirex MR 110 ZSi EVO 2 and the MR 130 ZSi EVO 2 – are ideal for processing reclaimed

asphalt pavement (RAP) and demolition concrete into value-added materials. The MR 110 ZSi EVO 2 is the slightly smaller version of the MR 130 ZSi EVO 2. EVO 2 represents the continuing evolution of the successful EVO Contractor Line, with additional benefits in terms of economy and operational safety.

|

|

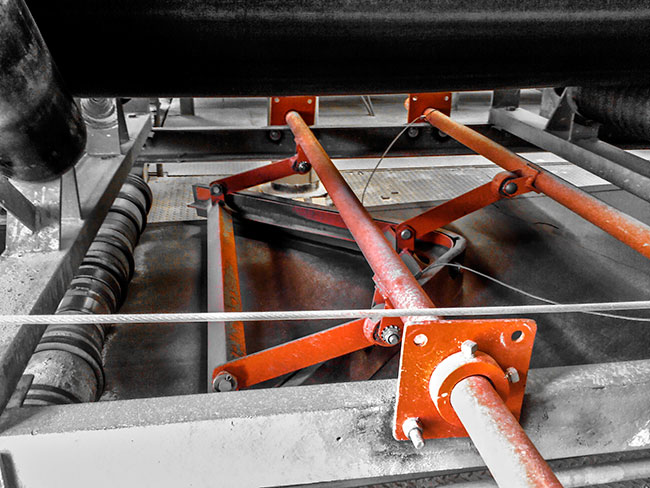

Martin Engineering

A global leader in bulk material handling technology offers v-plows and diagonal flows to reduce fugitive material entrapment and protect conveyor tail pulleys. The family of Martin Engineering products delivers consistent blade pressure across the belt plane, with specific designs for regular- and heavy duty applications, reversing belts and wing pulleys. The result is improved conveyor performance and prolonged belt and tail pulley health, reducing maintenance and contributing to a safer work area.

|

|

Volvo CE

The Volvo L250H wheel loader is a high production machine designed to deliver excellent productivity and profitability in applications including quarry, mining and heavy infrastructure. Operators will experience short cycle times, high breakout force and excellent controllability with this heavy-duty machine. The L250H is perfectly matched to on-highway trucks and will load a 25-ton triaxle on-highway truck in two passes — two full buckets for one full truck.

|

|

Wirtgen Group

A large cold mill with a hydraulically driven milling drum that’s movable from side-to-side is at the heart of the new Wirtgen W 200 Hi. This revolutionary design solves a number of user problems, and is based on the proven W 200i/W 210i platform. The W 200 Hi milling drum offers a hydraulically driven milling drum assembly that can be displaced 16 in. (400 mm) to the right or the left, providing contractors maximum flexibility for operating in tight quarters.

|

|

Superior

Superior’s Aggre-Dry Dewatering Washer is a single machine integrating a fine material washer and a dewatering screen. Sand processed through the equipment is stockpiled with a moisture content of just 8%, meaning the saleable product requires no drying time and can be accessed immediately.

Alternative uses to this technology include traditional sand screws, which produce high moisture material that can takes weeks to dry; dewatering screens without partner material washers lose up to 15% of sand to waste ponds; and cyclones use excessive amounts of horsepower, at least double the consumption of an Aggre-Dry Dewatering Washer.

|

|

McCloskey

AGG1 visitors will get a first look at McCloskey International’s new jaw crusher, the J45. On display at Booth 1064, the J45 has the power and production of much larger crushers in a smaller and more efficient footprint. A faster jaw speed also delivers more production with more material passing through the crushing chamber. Rugged and versatile, the J45 has undergone rigorous field-testing to ensure the reliability required for the toughest projects around the globe.

|

|

Allied

The newest addition to Allied’s Pedestal Breaker System line, the PowerPortable boom system, can be used with stationary or wheel and track-mounted mobile crushers. Built around Allied’s Rammer, AR Series™ and Hy-Ram® hydraulic hammers, the 350 to 1400 class hammers are mounted on a special low-profile boom that adds minimal height and weight to the crusher. The boom offers reaches of 10 to15 feet, allowing the PowerPortable boom system to reach both the crusher and feeder, if necessary.

|

|

ADM

EX Series asphalt plants from ADM produce 100 to 425 tons per hour at a very low cost per ton. Using counterflow technology, the EX Series has separate drying and mixing zones to achieve the maximum level of heat transfer and fuel efficiency. Furthermore, this system virtually eliminates unsafe hydrocarbon emissions. To make the plants even more environmentally friendly, ADM designed the system to reintroduce residual gases back to the drum’s combustion zone.

|

|

Vogele

The new 10-ft. Vögele Vision i-Series pavers represent the next generation of Vision pavers for the 21st century. The tracked Vision 5200-2i and wheeled Vision 5203-2i pavers are designed for the requirements of the North American market. These versatile pavers are suitable for urban applications, as well as for highway, airport and commercial work. The Vision 5200-2i and 5203-2i are equipped with ErgoPlus, Vögele’s revolutionary total design concept for easy paver operation.

|

|

CASE

Showcased in the CASE booth (1446) at World of Asphalt 2015 will be the new CASE DV209C, which gives road builders more control and versatility to dial in compaction performance to match each lift. The DV209C features a frequency range of 42 to 55 hertz standard and 46 to 67 hertz high frequency. This higher frequency range gives operators control over compaction performance based on the thickness and density requirements of the lift. When combined with variable amplitude settings (.22 to .6 millimeters), these machines can be dialed in to better handle thinner lifts (low amplitude/high frequency) and thicker lifts (high amplitude/low frequency). Centrifugal force can also be dialed in (15,736 to 21,582 pounds) to best match the thickness of the lift and the desired depth of compaction.

|

|

Hazemag

HAZEMAG Wobbler Feeders are proving their worth around the world. These units are engineered and designed to ensure application success, flexibility and field proven reliability. One of the largest cement plants in the world has processed well over 13 million tons of material without a single downtime incident.

|

|

W.S. Tyler

The new Hydro-Clean effectively cleans deleterious material from aggregate, recycled and other minerals while reducing water consumption by up to 75 percent over traditional log washers. Unlike traditional washing systems which can require up to three screens along with a log washer or screw, the producer only needs an additional wash screen for the Hydro-Clean’s discharged material. The Hydro-Clean is available in four model sizes that produce 20 to 400 TPH, depending on the application: the 350, 700, 1,000 and 2,000.

World of Asphalt/AGG1 comes to the Baltimore Convention Center March 17-19. For the latest product releases, as well as updates from the show floor, visit rocktoroad.com.

Print this page